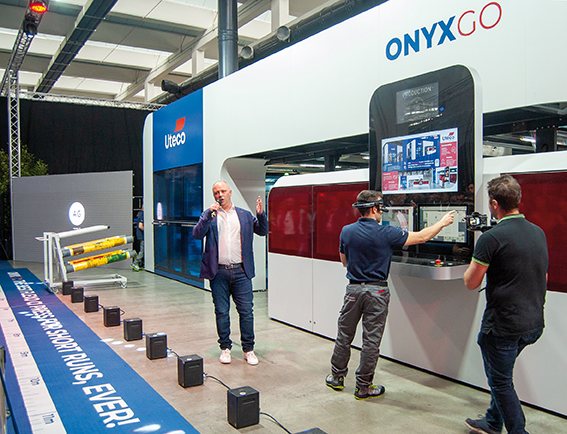

With a great event that was held last May 11 at the Converdrome of Colognola ai Colli (Vr), the entire Uteco management welcomed almost 200 visitors from all over the world for the launch of the new OnyxGO, of the SleeveBot for automatic sleeve change, finally also announcing a new strategic partnership with GAP

Great satisfaction at Uteco for the success of the Open house, May 11 at company’site and May 12 with side events dedicated to customers who were able to taste and enjoy Italian hospitality, two days full of technical and strategic content, presented by the company’s top management headed by Eng. Aldo Peretti, Executive Chairman of Uteco with the management team: CEO Mario Tomasi, Andrea Caselli, Alessandro Bicego who headed the development team of the new OnyxGO, Patrizia Pinto, Stefano Manfrin, Corinne Carone and finally Mattia Carpinetti who detailed all the innovations of the new flexo machine by Uteco, specifically designed for short runs.

OnyxGO, which we have already extensively described in one of our articles published in Converter in November/December 2022 (article also available on our portal converter.it) is a concentrate of innovations, technology, and design functional to ergonomics and energy saving, which make it the most compact 8/10 color central drum flexo machine on the market today. 10 meters long, 5 meters wide for a total occupied area of 50m2, capable of reaching a maximum speed of 400 meters per minute, it is characterized by various automatisms aimed at the maximum reduction of material waste. In fact, announced with a start-up waste of 18 meters during the job changeover of the demo, in reality after only 8 meters the machine went into full production. What is most striking, obviously in addition to the technological aspects, is the great attention paid by Uteco to the design of this model, which is not an end in itself, but largely aimed at improving the ergonomics and the user experience of the machine operators , with the control pulpit on the machine that can be raised or lowered according to the operator’s needs, who can govern the entire printing process from there, even comfortably seated. We remind that OnyxGO is the result of over 200 interviews that Uteco conducted with its customers all over the world and therefore it is the perfect synthesis of a project born practically from the bottom up, from the needs of the market.

OnyxGO, which we have already extensively described in one of our articles published in Converter in November/December 2022 (article also available on our portal converter.it) is a concentrate of innovations, technology, and design functional to ergonomics and energy saving, which make it the most compact 8/10 color central drum flexo machine on the market today. 10 meters long, 5 meters wide for a total occupied area of 50m2, capable of reaching a maximum speed of 400 meters per minute, it is characterized by various automatisms aimed at the maximum reduction of material waste. In fact, announced with a start-up waste of 18 meters during the job changeover of the demo, in reality after only 8 meters the machine went into full production. What is most striking, obviously in addition to the technological aspects, is the great attention paid by Uteco to the design of this model, which is not an end in itself, but largely aimed at improving the ergonomics and the user experience of the machine operators , with the control pulpit on the machine that can be raised or lowered according to the operator’s needs, who can govern the entire printing process from there, even comfortably seated. We remind that OnyxGO is the result of over 200 interviews that Uteco conducted with its customers all over the world and therefore it is the perfect synthesis of a project born practically from the bottom up, from the needs of the market.

Active Pack technology, concrete attention to sustainability

The Veronese manufacturer’s attention to sustainability aspects is interesting, which on the OnyxGO are summarized in the Active Pack, a package of top-level technological solutions, each of which leads to concrete savings in energy consumption and consumables that Uteco has calculated approximately amount to €100,000 a year.

The Veronese manufacturer’s attention to sustainability aspects is interesting, which on the OnyxGO are summarized in the Active Pack, a package of top-level technological solutions, each of which leads to concrete savings in energy consumption and consumables that Uteco has calculated approximately amount to €100,000 a year.

Active Start, Active Dry and Active Ink are the three modules that make up the Active Pack; the first is dedicated to machine setup which is finished in 3 minutes with minimal material waste, thanks to which around €35,000 of waste is saved.

The improvement in energy consumption is instead guaranteed by Active Dry which distributes air flows according to the printing characteristics of each unit, for a 50% reduction in energy consumption and finally Active Ink with an ink dosing system optimized according to the real needs of each single printing unit thanks to which energy savings of approximately 60% are obtained.

OnyxGO turns out to be an extremely versatile printing machine and suitable for numerous multi-material applications (plastic film, aluminum, paper, cardboard, laminates). To facilitate the choice of configuration by the customer, based on the different applications to be created, Uteco has also provided 4 kits for water-based applications (water-based kit), paper and cardboard jobs that require particular ribbon tension configurations (Kit Heavy Duties), for jobs realized in hot and humid areas (Kit Tropicalization), and for productions that need to process aluminum (Kit Aluminum).

The presentation and the press demo were captivating, spectacular and very well organized, which was undoubtedly the highlight of the day.

Synergy with GAP Italy, specialist in extrusion technologies

The film production process is directly connected to the printing and converting phases and such an important link for the packaging market could not be missing in Uteco’s offer and therefore the joint venture was made official during the open house with GAP Italy, an Italian company from the province of Novara, on the market since 2004, and technical spin-off of Prandi-PolyTech, capable of growing in 23 years of activity with first-rate technological solutions, among which the blown film extrusion equipment launched in 2015 for the production of a material composed of 27 micro layers, 30% thinner but with extremely high-performance and sustainable thanks to material savings, completely recyclable. This partnership will allow the expansion of GAP and Uteco, which will present themselves in their respective markets with integrated technological solutions for the entire printing and converting market.

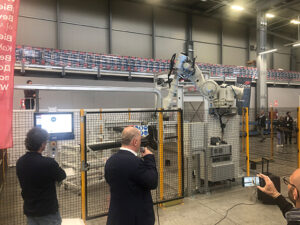

SleeveBOT for automatic sleeve change

The last news of the day, unveiled during the tour of the production departments dedicated to long runs flexo, concerned the innovative project patented by Uteco for the automatic change of sleeves. It is an anthropomorphic robot which, thanks to a single mechanical arm, can handle sleeves of any diameter, without the need to change grippers. In addition to managing the sleeve change in total autonomy, the system also has a “washing” function which positions the sleeve at operator height who can intervene for the cleaning operations of the cliché before archiving. It is a solution that projects the process towards an increasingly automation and certainly interesting for large companies. Sleevebot nonetheless amazed attendees with its unparalleled speed and versatility, providing a vision of the future of printing and converting which will increasingly be characterized by automatically managed processes.