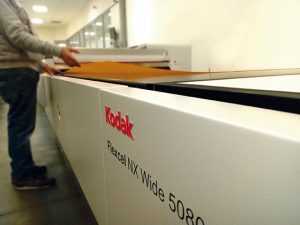

Since its inception in 1997, Mavigrafica has chosen to be a prepress service for the flexo sector and from the very beginning it has stood out for its innovative solutions. In 2008 Mavigrafica recognized Kodak as the right partner to differentiate itself on the market in the flexo plates sector, purchasing first in Italy a Flexcel NX plate production system, today it uses 3 Flexcel Nx Wide 5080 systems

Since its inception in 1997, Mavigrafica has chosen to be a prepress service for the flexo sector and from the very beginning it has stood out for its innovative solutions. In 2008 Mavigrafica recognized Kodak as the right partner to differentiate itself on the market in the flexo plates sector, purchasing first in Italy a Flexcel NX plate production system, today it uses 3 Flexcel Nx Wide 5080 systems

Mavigrafica knows Flexcel NX solutions at drupa in 2008, and “my father, who was enthusiastic about them, decided to bring the project to the company. After an inevitable running-in period, which allowed us to assimilate its characteristics and exceptional print qualities, we faced the market, still unaware of the potential of the product, which was in fact subject to not a few criticisms. But we can say that since then many customers have changed their minds and it has become our flagship product. There hasn’t been a company in this sector in Italy that in such a short time has managed to grow so much thanks also to these systems, becoming a very strong reference point on the market”, explains Alessia Vitale, prepress graphic designer, daughter of Maurizio Vitale, owner of the company, who has an office in Fisciano (SA) and one in Pioltello (MI).

“Over the years Kodak, now Miraclon, has been an excellent partner, there is no doubt that many things have changed but the important thing is that they have always remained very proactive. “The people who work between us and the company are wonderful and always available, they do their utmost to be close to our requests and solve any problems; we are very satisfied and we certainly hope that we will continue to be so also in the future”, says Alessia.

“Over the years Kodak, now Miraclon, has been an excellent partner, there is no doubt that many things have changed but the important thing is that they have always remained very proactive. “The people who work between us and the company are wonderful and always available, they do their utmost to be close to our requests and solve any problems; we are very satisfied and we certainly hope that we will continue to be so also in the future”, says Alessia.

Before getting to know this product, Mavigrafica sailed in unknown waters, today its customers have been able to solve various critical issues using Miraclon flat top plates, naturally combined with experience and professionalism of the company, especially in pre-press processing.

Currently the 3 Kodak Flexcel Nx Wide 5080 systems with 1270 x 2032 plate format, combined with other solutions such as the various Advanced Digicap that allow you to print on all surfaces with a more uniform ink distribution and high density, thanks to the surface pattern that is applied to the polymer, are installed at two Mavigrafica sites in Fisciano (SA) and Pioltello (MI). Thanks to this combined system is possible to use anilox with lower volume but with high densities, cleanliness of texts and exceptional shades.

“We also have special screens including, for example, the Maxtone SX that allows us to improve the highlights even more, it assures less reduced set-up time and consequently less waste, and also with long runs it is not necessary the cleaning of polymers. All this has promoted us by increasing year after year the number of customers and also our turnover “, says Alessia.

Perfect prints, always, even when you switch from offset or gravure to flexo

In order to guarantee customers a high quality standard, Mavigrafica bases its work on full control of the entire prepress flow, following customers starting from the first development steps of the project. The services it offers are many: from the graphic processing of the file, customizing it according to the needs of the converter, to color profiles up to the supply of flexo plates. The company is always close to the customer even with an area dedicated to the creation of mock-ups in 3D models that allow you to give the product a 360 ° view, also implementing web solutions, such as creating and managing web-sites. Customers include not only printers but also several important brands, both for Italian and foreign market.

In order to guarantee customers a high quality standard, Mavigrafica bases its work on full control of the entire prepress flow, following customers starting from the first development steps of the project. The services it offers are many: from the graphic processing of the file, customizing it according to the needs of the converter, to color profiles up to the supply of flexo plates. The company is always close to the customer even with an area dedicated to the creation of mock-ups in 3D models that allow you to give the product a 360 ° view, also implementing web solutions, such as creating and managing web-sites. Customers include not only printers but also several important brands, both for Italian and foreign market.

“Working with Flexcel NX gives us the certainty of achieving in print a result that remains stable from the first to the last meter of film, Flexcel NX polymers allow us to achieve an excellent result if you compare the color proof to the machine sheet: this is our strength. Many packaging items that were previously made in offset or gravure have been converted to flexo thanks to the high performance of Flexcel NX. So, in addition to our experience in prepress, we were able to reach places where flexo market had not yet arrived”, explains Alessia.

A continuously growing service

Mavigrafica was born in 1997 founded by Maurizio Vitale as a communication agency. Over the years it has increasingly specialized in the management of graphics and prepress in the flexo segment, then expanding the range of services with the supply of plates in 2006. “To date, the company is a certified industry that relies heavily on new recruits. Each of us carries out specific tasks, in different company departments. I have always followed my father’s work with enthusiasm, I approached the world of graphics more and more closely following the evolution of flexo printing from analog to the arrival of digital. In 2010 I actively entered the company specializing in prepress and to date I follow customers, not only as a graphic designer but, where required, also as a consultant on new product lines or as a support technician during printing machine start-ups”, tells us Alessia.

Mavigrafica was born in 1997 founded by Maurizio Vitale as a communication agency. Over the years it has increasingly specialized in the management of graphics and prepress in the flexo segment, then expanding the range of services with the supply of plates in 2006. “To date, the company is a certified industry that relies heavily on new recruits. Each of us carries out specific tasks, in different company departments. I have always followed my father’s work with enthusiasm, I approached the world of graphics more and more closely following the evolution of flexo printing from analog to the arrival of digital. In 2010 I actively entered the company specializing in prepress and to date I follow customers, not only as a graphic designer but, where required, also as a consultant on new product lines or as a support technician during printing machine start-ups”, tells us Alessia.

As far as the Pioltello site is concerned, the graphic department already present in the Milan area since 2013, Mavigrafica has chosen to implement also there the production of photopolymers to be even closer to customers who are giving great confidence and satisfaction to the company.

“The turnover of Mavigrafica speaks clear: since the introduction in 2008 of Flexcel NX it has always had a positive trend, despite the difficult historical moment that we experienced last year and that we are experiencing today, we can however say that the packaging sector has never interrupted its path. Mavigrafica expects continuous investments and an ever greater margin for growth, in short, there is still a lot to do in this sector and other markets yet to be explored. At the moment we are working hard on automation and process control, there are implementations that will ensure greater efficiency of products, bringing news, quality and service.

“The turnover of Mavigrafica speaks clear: since the introduction in 2008 of Flexcel NX it has always had a positive trend, despite the difficult historical moment that we experienced last year and that we are experiencing today, we can however say that the packaging sector has never interrupted its path. Mavigrafica expects continuous investments and an ever greater margin for growth, in short, there is still a lot to do in this sector and other markets yet to be explored. At the moment we are working hard on automation and process control, there are implementations that will ensure greater efficiency of products, bringing news, quality and service.

Mavigrafica award-winning and certified quality

The company won in two categories: Flexo printing on paper – wide web, that won the first prize at 2016 Best In Flexo and Flexo printing on film – medium web, that won the first prize at 2017 Best In Flexo.

The company won in two categories: Flexo printing on paper – wide web, that won the first prize at 2016 Best In Flexo and Flexo printing on film – medium web, that won the first prize at 2017 Best In Flexo.

In addition, in 2019 Mavigrafica obtained the Miraclon Kodak Flexcel NX certification, which is an official confirmation of the company’s ability to produce plates of constant high quality and compliant with the rigorous production standards defined by Miraclon. “Flexcel NX has played a very important role in the success of our business over the past eleven years. The high quality it offers has set the de facto standard for our customers and continually attracts new business activities. The certification obtained testifies our high production standards and consistency”, commented Maurizio Vitale.