Packaging prototyping is the executive phase immediately following the technical drawing. It is essential to create a functional model and to foresee a multiplicity of data such as the mechanical characteristics of the materials involved. Type, reaction to stress and solicitations given by use, attributing to the packaging not only an aesthetic characteristic but also durability and consistency, therefore the ability to contain the product it is intended for, limiting imperfections

By Diego Lucarini – Technical teacher and trainer

Thanks to:

Democenter SIPE Foundation, research and innovation center.

Exmplar s.r.l. for Abaqus Simulia – Dossoult Sistemes.

B+B international s.r.l. for ArtiosCAD – Esko.

Cardboard converting technical drawing is a set of tricks linked to the folding theory, which vary according to whether corrugated or stiff cardboard is examined. The designer specialized in the packaging industry must make a sketch that includes the nomenclatures and tolerances of the type of carton involved.

In fact, folding and creasing tolerance vary according to the thickness of the paper and the number of ?/ sheets, thickness/kraft, sheets/sine. The creasing needs a dedicated graphic nomenclature², which distinguishes the crease generally indicated with a hatch of the blade, a continuous line and therefore finalizes the design to the creation of the die, flat or rotary.

In the early days of automatic CAD design dedicated to cardboard converting, the only tools that were suitable to the management of a drawing that involved extrusion and boolean functions of section, fusion or subtraction, aimed at simulating 3D packaging, often engaged the designer in an upstream calculation of folding tolerances. However, even if the 3D solution was absolutely representative, only the sampling allowed a real ascertainment of the result. A substantial evolution of the design and prototyping method has been offered by Esko software, that has developed a series of programs dedicated to packaging design, among these programs ArtiosCAD stands out, whose extensive library includes multiple types of FEFCO and GIFCO corrugated cardboard. In addition to a large number of tricks for setting up the die and the graphic mockup.

ArtiosCAD is the leading software for the design and management of all types of cellulose-based rigid packaging. An important rendering engine manages the three-dimensional parametric design that simulates the closure of the packaging, applying what has already been expressed in summary. See creasing

ArtiosCAD is the leading software for the design and management of all types of cellulose-based rigid packaging. An important rendering engine manages the three-dimensional parametric design that simulates the closure of the packaging, applying what has already been expressed in summary. See creasing

The ability to quickly perform a correct three-dimensional drawing does not exclude the full compatibility of ArtiosCAD with cutting plotters, essential machinery in the processing of the cardboard converting prototype. But the prototype made with the cutting plotter, however correct, does not allow a series of observations, values not detectable with the naked eye.

In the study of cardboard packaging, the verification of the physical-mechanical characteristics related to the strains/stresses due to use, transport or other types of load or impact are left to specialized laboratories, which through special machinery assessed the degree of fragility, packaging possibility and transportability. An onerous laboratory process. In fact, these analyzes appear to be the pure prerogative of packaging dedicated to certain sectors, such as high-tech aerospace, where even in the delivery every detail must be evaluated to avoid micro damage.

The need to be able to optimize the prototype by establishing the effective solidity of the box made in corrugated cardboard, in other materials, as a hybrid solution between polyethylene and paper, or with newly developed materials, has engaged me in a careful search for valid alternatives. An alternative that I believe takes the form of the Abaqus SIMULIA simulation software.

Working coordinating ArtiosCAD with Abaqus allows you to analyze a multitude of variables and parameters, making the packaging scientifically safe¹. To evaluate the above, an exercise follows that examines a solid geometry that will lend itself to simulating a box at the base of which we will apply a stress or force, to detect the actual ability to contain and protect the product.

Case study:

The first step in drawing a sketch in Artioscad is related to choosing the type of corrugated cardboard, evaluating the options in a library included in the software installation. I choose FEFCO l-125E Kraft carton. A single wave product, suitable for secondary rigid packaging, that is not aimed at direct contact with food.

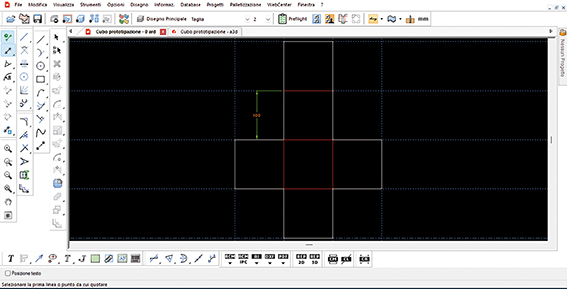

Once the polyline/geometry has been chosen, I start drawing the packaging, first in plan, providing a perimeter of 40 cm for each face (tab). As already stated, my aim is to understand the degree of compatibility between the two platforms, for this reason I opt for an essential geometry, without all those cardboard characteristics that allow closure, such as flaps intended for joints or to receive a glue point.

In this case study, the only carton characteristics are the type of cardboard applied and the four folds/creases. The polylines allow you to quickly draw the geometries to which the program automatically assigns the folding value expressed by the red lines.

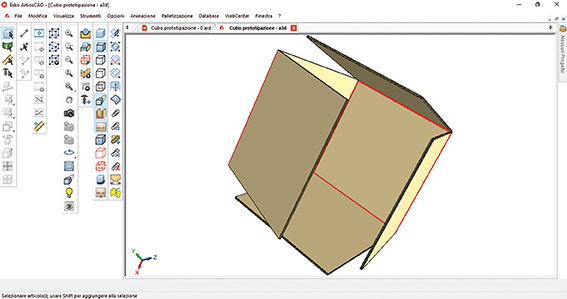

The convert 3D option starts the ArtiosCad render engine functionality, allowing you to simulate the partial or complete closure of the packaging. An exact value of folding tolerances is applied to the creases, perfectly respecting the thickness and the number of waves of the cardboard and the thickness of the paper. See assigned values.

The parametric prototype is complete, the program allows us to evaluate the correct assembly of the packaging through 3D.

The globality of variables and findings related to the characteristics of a prototyping study of a container to which we expect to assign, hypothetically, a longer life in terms of use, can foresee in addition to what has been carried out in a structural mechanical simulation laboratory, starting from the characteristics of the applied material, compression tests, thermodynamic stress, etc.

Returning to the description of the steps of the exercise, once the 3D is completed, we select the design and choose the ArtiosCAD ” Output ” command to export the parametric model, the software allows you to choose different computer extensions. Abaqus also allows you to import different types of parametric projects developed in other CAD programs. Having found that the .IGSᶾ computer extension is a compatible format between the two platforms, I proceed with the import of the extruded into Abaqus, this is cataloged as a PART list, this function is assigned as it is already a not-native 3D element.

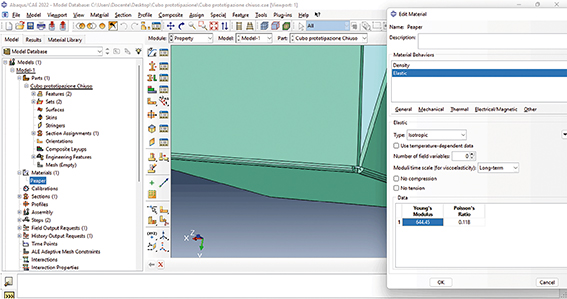

The first phase will be to rename the IGS Geometry design and assign the characteristics of the material associated with the 3D object.

It must be said that Abaqus program allows excellent solid modeling and as such also the details of the imported extruded are described with absolute care.

The passage dedicated to the material does not require the type and characteristics of the cardboard selected from the FEFCO library, but more methodical values, to mention just a few, the mass density, which varies according to the paper manufacturing process, in this case recycled corrugated pulp 463.7 g/mq* the elasticity values, the Poisson ratio 0.118 and Young Modulus 644.45**.

The following parameters are relevant to the choice of the test to which the material will be subjected. We then simulate the stress value caused by a force expressed by the pressure applied by the bulk. Through the ” Load ” function we apply a magnitude/force value with respect to a surface or more selected. In our case we select the upper area of the basic tab. ”FIx to ground” allows you to simulate the stability of the object on the ground or in the supporting surface of the packaging.

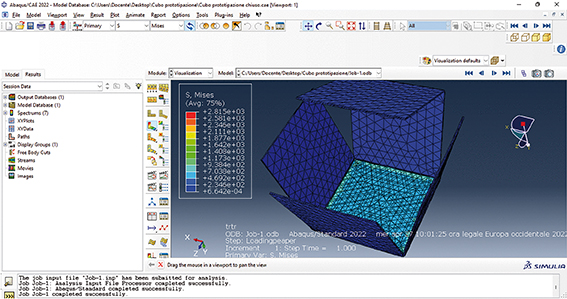

Once all the parameters have been set, all that remains is to switch the parametric into polygon mesh. Meshare, that is to fragment the drawing in number of points and exponential planes, implies some precautions, compared to a developed native 3D sketch. The mesh allows you to simulate the impact by interacting between the magnitude values and pressure points applied on the cross-linked plane of the parametric design.

The result will be the verification of the solidity of the packaging with respect to the exercise of solicitation of a determined force. The image shows how the degree of stress is greater in the creasing area, the color is associated with the level of stress given by the force field. Another value, the deformation of the mesh, always due to the applied force test.

Obviously there are many variables starting from the fact that corrugated cardboard is a material composed of a set of layers that have solids and voids, measures that can be included in a second step but which in this demonstrative case, are not included.

Obviously there are many variables starting from the fact that corrugated cardboard is a material composed of a set of layers that have solids and voids, measures that can be included in a second step but which in this demonstrative case, are not included.

Consequently, an optimal product is an index of production and energy savings, a reduction in waste, consequential values to the entire work process. In many small and medium-sized cardboard converting companies, the choice of the type of cardboard or material, with respect to the product to be packaged, is often dictated by the designer’s experience, combined with cost requirements. Furthermore, the work of these two applications allows an effective verification of the solidity and durability of the container, and other structural needs, see safety, to be associated with the packaging.

Notes

1) The exercise does not include chemical tests, such as the migration of the pigments of the inks, but only physical and mechanical tests. Other tests are deferred to inclusive developments including further skills.

2) The graphic nomenclature shown is purely formal, therefore it can change based on the agreements between the designer, the company and die manufacturer, see the assignment of colors and not of the hatch in ArtiosCad.

3) Initial Graphics Exchange Specification (IGES) defines a neutral data format that allows for the exchange of data, graphics files and information between CAD systems.

* Numerical Prediction of Equivalent Mechanical Properties of Corrugated Paperboard by 3D Finite Element Analysis. Department of Bio-Industrial Machinery Engineering, Pusan National University, Miryang 50463, Korea; parkjssy@pusan.ac.kr (J.P.); changsewon@gmail.com (S.C.) 2 Department of Logistic Packaging, Kyongbuk Science College, Chilgok 39913, Korea * Correspondence: hmjung@kbsc.ac.kr; Tel.: +82-54-979-9558

** Contribution to the modelling of the corrugated cardboard behaviour. Institut PRISME/LMSP, UPRES E.A. 4229, Université d’Orléans, Polytech’Orléans, 8 rue Leonard de Vinci 45072 Orléans Cedex2, France