Stand to feature full line of Asahi Photoproducts for flexographic printing with focus on AWP™-DEW and AWP™-CleanFlat water washable flexo plates for high quality and sustainable production of labels & packaging, in Pavilion 9, Stand P17 – R18 at the show.

Stand to feature full line of Asahi Photoproducts for flexographic printing with focus on AWP™-DEW and AWP™-CleanFlat water washable flexo plates for high quality and sustainable production of labels & packaging, in Pavilion 9, Stand P17 – R18 at the show.

“We are looking forward to connecting with long-term customers and meeting new ones at this important in-person event,” says Andrea Belloli, Italian Branch Manager. “Visitors to our stand will see a reflection of our dedication to sustainability, especially with our innovative line of water-washable CleanPrint flexo plates. We will be discussing their specific flexographic needs with visitors, and will have experts on the stand that can recommend the best solutions for them moving forward. It is shaping up to be an exciting show!”

No Solvents Required

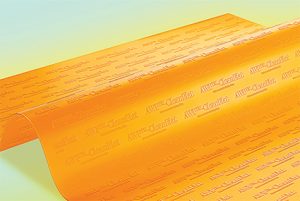

Asahi AWP™ CleanPrint water-washable flexographic plates are processed without VOC-based washout solvents, they use less energy in the production process and deliver a faster time to press than VOC solvent-based plates. Asahi´s CleanPrint water-washable flexographic photopolymer plate technology’s ability to deliver high-quality print performance is a result of its engineered photopolymer chemistry design. The water-wash technology also features a low surface energy plate resulting in higher printing press efficiency and less printing wastage. All of these elements make them the most sustainable flexographic plates in the industry. In addition, AWP™-DEW CleanPrint plates deliver extremely high-quality print due to their precise registration and ability to deliver perfect printing balance between highlights and solids.

Asahi AWP™ CleanPrint water-washable flexographic plates are processed without VOC-based washout solvents, they use less energy in the production process and deliver a faster time to press than VOC solvent-based plates. Asahi´s CleanPrint water-washable flexographic photopolymer plate technology’s ability to deliver high-quality print performance is a result of its engineered photopolymer chemistry design. The water-wash technology also features a low surface energy plate resulting in higher printing press efficiency and less printing wastage. All of these elements make them the most sustainable flexographic plates in the industry. In addition, AWP™-DEW CleanPrint plates deliver extremely high-quality print due to their precise registration and ability to deliver perfect printing balance between highlights and solids.

Asahi will be showing two members of the water-wash CleanPrint family:

- AWP™-DEW plates deliver extremely high-quality print due to their best-in-class finest highlights and good balance with homogenous solids.

- AWP™-CleanFlat plates are our new out-of-the-box water-washable FlatTop plate solution with high-quality printing press consistency for longer runs, including the usage on abrasive substrates. The solution also delivers an efficient print production, reduced print waste and good solid ink density.

- At the same time, both plates result in a sustainable improvement of the printer’s carbon footprint, increasing print efficiency.