“The technology we are most proud of goes home in the evening” – Box Marche

Box Marche was born in 1969 from a family of farmers in Corinaldo and represents an example of transformation from peasant civilization to industrial reality that does not distort the characteristics of the environment and the territory in which it developed. The business began with the production of shoe boxes for the local footwear sector, and then the company transformed, in the mid-1980s, its production and commercial structure towards other sectors and geographical areas. The “cardboard converting” vocation takes on more and more consistency by directing the activity towards national and European market with prevalence in the food, beverage and household sectors.

Today Box Marche is a reality that has 66 employees, produces around 75 million pieces a year with two traditional production lines with 100×140 and 70×100 formats and a third entirely digital one.

The company carries out its activities in the factories of Corinaldo headquarters and in the new production unit launched in 2020 in Pergola for the production of Halopack food trays.

The organization is designed following corporate vision and mission, which encompass the company’s reference values, such as honesty, responsibility, balance and good relations in industrial practice, as well as placing “people” at the center of its operations. It is also oriented towards offering value proposals which, through a differentiation of products and services, can generate concrete advantages and solve problems for customers. The goal is to be suppliers of solutions, of ideas, to share loyal, serene and exclusive relationships over time.

The corporate functions are designed to increase the level of service offered, improve internal processes and obtain greater efficiency with the aim of making people passionate, multi-skilled and interdisciplinary to fuel advantages and offer products and services following a “customer focus” approach.

What products are offered to the market?

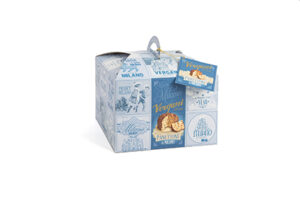

Box Marche designs and manufactures customized packaging, cases, bands, boxes, bags in box, exhibitors and displays in folding carton, corrugated and laminated cardboard. For its customers, it plays the role of specialist consultant offering a wide range of innovative services that go beyond the supply of a box, developing valuable processes adapted to the specific needs of each project for different product sectors, to which it totally dedicates its technical and creative resources, offering a high level of assistance and optimized supply chain solutions.

Box Marche philosophy “living outside the box” means thinking outside the box, setting no limits to progress and being obsessed with customer satisfaction, solving problems and generating benefits.

Box Marche specializes in the production of bags in box and wine boxes in laminated cardboard, one of the products with a marked ecological connotation, accompanied by a skillful structural design of the pack and specific advice on finishings and printing enhancements.

Pergola site is dedicated to the production of Halopack, the first cardboard tray for foods packaged in a protected atmosphere (MAP) and Skin, the definitive solution for reducing the use of plastic by over 90%. Recyclable in paper but with a removable barrier liner, Halopack has obtained level B Aticelca certification which guarantees its recyclability in paper even without separating the film from the cardboard base. In addition to enhancing the customer brand’s green soul, it can be printed on both sides, greatly enriching the communicative potential of the packaging.

Face to face with Tonino Dominici, president and CEO of Box Marche spa

How has the relationship between Box Marche and B+B International developed over the years?

“We have been collaborating with B+B International for over twenty years. The first activity was the automation of the technical office with the introduction of specific and highly performing CAD/CAM technologies, initially with ArtiosCAD design software and subsequently with the installation of the Kongsberg XL20 plotter still in excellent shape. We then started the software automation process by implementing the Packway management software.

In this phase there was a deep integration with the factory, which is undoubtedly the beating heart of our cardboard converting company, installing the terminals on the machines in each work center.

This entirely computerized management under the direction of a single computer system has allowed us to achieve the company’s governance and control objectives through management analyses and detailed reporting, especially in terms of job order costs and subcontract management. From the beginning this was the main reason because we decided to make such a demanding investment as the change of management system. Although the previous software architecture had supported us for several years, we knew that we had to change step gradually, it was clear the need to have a modern, specific software that really allowed us to manage in detail all the products offered by our company and all operational processes in order to obtain meaningful data”.

What determined the Packway software re-engineering plan?

“Over the last three years we have supported an extremely significant investment program in machinery as it included a new offset printing machine, two autoplaten die-cutter, a folder-gluer and a robotic system for automatic palletization at the end of the line for the three folder-gluers. We were also convinced that to be able to fully use the potential of these new machines, we had to intervene equally heavily in the automation of processes, organization and software.

We realized the strategic importance of seeing technological innovation and digitization no longer only through the introduction of new modern and highly performing machinery, but combining them with totally interconnected software technologies, a deep training of personnel, daily measurement and control tools of the company.

For this reason, during 2022 we made important investments in the entire corporate server-network infrastructure, in the updating and extension of the Packway management software and in the training of human resources, who for Box Marche have always been the technology to be most proud of.

With the exception of some specificities, we must remember that our products are easily reproduced, so to win we must focus on efficiency, which passes through cost control, process optimization, waste reduction, management control and by a software that supports the entire company in a strategic key. However, we are aware that the “less policy” does not work, therefore what is told above is necessary, indispensable, as long as it is used to create greater value for the customer and for our company”.

What exactly is the re-engineering of the Packway software?

“As already stated, over the last few years we have given priority to investments in machinery, while continuing with the “Kaizen” continuous improvement path by applying the principles and methodologies of the lean organization, giving great importance to people. In all of this it is evident that something could have remained a little behind and once the new machines and procedures were started up, it became clear that the time had come to intervene on the entire corporate software infrastructure. Thanks to the consolidated relationship and the trust established over the years with the people of B+B, we were able to carry out a transparent and truthful analysis. Since also B+B adopts lean methodologies in the analysis and implementation phase of the Packway management software, it was easy to act as a team.

We carried out a careful analysis of what were the objectives desired by the management and then a detailed analysis for each company department, scientifically identifying the current situation and the situation to be achieved, to respond both to governance objectives but also to the wishes of each single department. The achievement of these objectives was possible through the updating of the server infrastructure, the updating of the Packway software, the installation of new modules not previously present and an important training plan, a total of 60 days of work distributed over four months. Specifically, a lot of support was given to the commercial structure by implementing the CRM and the management of the technical office with the Docupoint module, the new version of technical sheets, estimates and orders, a massive intervention on the entire production area including planner and new machine terminals, was automated the warehouse area with the implementation of the Packway Logistics module for raw materials, semi-finished and finished products, all integrated with our robotic warehouse at Corinaldo site, multi-warehouse management, deposits at external logistics , consignment stock, etc.

The updating of what was already present and the insertion of all these new modules of the Packway software have allowed us to manage all the processes of our company informatically, to strengthen the reporting system and obtain a complete, immediate and easy to use management system, taking advantage of the new directional analysis dashboards based on web technologies and Microsoft Power BI”.

What do digitization and industry 4.0 mean for Box Marche?

“Knowing your own data is just as important as the quality of the product to be delivered to the customer.

Regardless of the tax benefits which are undoubtedly important, the interconnection between the machines and the management software really allows you to have control over your company.

The paradigm through which investments are evaluated and chosen has changed, today we could no longer imagine investing in technologies worth millions of euros without having total and precise control, therefore in this context digitization and industry 4.0 are precisely the intersection between machine, software and above all people. An alchemy of elements, a formula which, if perfectly calibrated, offers concrete and tangible advantages to the company, making it much more attractive and competitive.

The correct management control, seen from a strategic and proactive perspective, allows to improve the analysis of the market, of the sectors served and of the customers, allowing to better calibrate the value proposal and face complex decisions with qualitative information.

The investments made in recent years have accelerated our improvement process. However, it should be recognized that the investments necessary to concretely implement the “digital transformation” must be consistent, i.e. both machines and software.

The investments made in recent years have accelerated our improvement process. However, it should be recognized that the investments necessary to concretely implement the “digital transformation” must be consistent, i.e. both machines and software.

The installation of a new machine requires a very expensive investment, but in terms of commitment of human resources it is rather limited, in fact we are talking about a dozen people.

Updating the management software or inserting new modules has a decidedly lower economic impact than that of a machine, while the involvement of the personnel is holistic, as it directly and indirectly involves all the collaborators of the company.

It is important to point out that the path of change had quite an impact, because we had to intervene on the organization and on the change of habits consolidated over the years.

The integration between the offices and the factory remains very strong because all data must be collected correctly. The amount of information available in the data sheet has once again proved to be the essential element for obtaining what was desired in relation to directional analyses.

With Packway, the process is currently managed at 360° and the results achieved have justified the efforts and investments made”.

What will the future hold for Box Marche?

“During the current year, a new production line will be installed which will be totally interconnected with the Packway management software and we expect to be able to complete all the technical documentation that will allow us to start expanding Corinaldo site in 2024. We will continue with the implementation of Packway, which will be integrated with ArtiosCAD design software in order to automate the quoting directly from a structural drawing as well as the automatic creation of the technical sheet. We will improve supply chain integration with both customers and suppliers and we foresee the installation of Packway E-Procurement to create new value for our customers. Also for these new important additions there will be the direct involvement of B+B International”.

“During the current year, a new production line will be installed which will be totally interconnected with the Packway management software and we expect to be able to complete all the technical documentation that will allow us to start expanding Corinaldo site in 2024. We will continue with the implementation of Packway, which will be integrated with ArtiosCAD design software in order to automate the quoting directly from a structural drawing as well as the automatic creation of the technical sheet. We will improve supply chain integration with both customers and suppliers and we foresee the installation of Packway E-Procurement to create new value for our customers. Also for these new important additions there will be the direct involvement of B+B International”.