By Stefano d’Andrea – trainer and consultant in the flexographic process

We receive and publish this report about this virtual event, which has stimulated and interested many operators in the flexographic sector

I had booked the hotel, bought the plane ticket, organized a lot of things with international flexographic friends who would participate in FTA 2020 Forum in Columbus, Ohio but… I am comfortably at my desk in front of my computer to follow the first virtual session of the Forum, that is not so virtual: we are talking about many practical aspects with a webinar mode that has become customary in these lock-down weeks. Fortunately, the organization of FTA did not find itself unprepared, thanks to the experience of the numerous webinars that are offered to members during the year.

Yes, but this is a very big webinar! With 875 registrations from all over the world and an average of 650 connections during the 6 hours (including lunch break) of the expected duration. The Forum program was kept as close as possible to the original live version but was split over 3 Wednesdays.

1st day

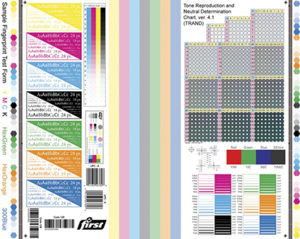

The first session of the day touched the relationships between the various roles in the production flow in terms of expectations and actual technical possibilities. The presentation was mainly intended for the production of cardboard packaging in pre-print and post-print to clarify how to correctly define expectations on the results of the printed product. Often the “brief” phase is underestimated or is based on previous experiences and characteristics of different printing systems, typically offset. The correct calibration and configuration of the flexographic system through the FIRST method allows the potential, the limits of the system and the expected quality of the finished product to be transferred to brands effectively.

The day continues by entering the practical aspects of the most important phase of the calibration of the flexographic system: optimization. This fundamental phase of the process control has been described with practical and operational details, as they are experienced by those directly involved who must manage the printing system.

The machine operator is in fact a fundamental pillar in communication connected to the process calibration phases, regarding the definition of the optimal parameters for the configuration of the printing system.

The optimization between ink and substrate to be printed is one of the most important parts, both in terms of compatibility between materials and in terms of interactions between colors that influence the final printed result. During the optimization it is necessary to pay particular attention to the number of variables to be tested because there is the risk of multiplying the various conditions with a considerable increase in the measurements to be performed to analyze the results.

The optimization between ink and substrate to be printed is one of the most important parts, both in terms of compatibility between materials and in terms of interactions between colors that influence the final printed result. During the optimization it is necessary to pay particular attention to the number of variables to be tested because there is the risk of multiplying the various conditions with a considerable increase in the measurements to be performed to analyze the results.

The result of the optimization must be proof that the system is under control, and that therefore it is possible to proceed with the subsequent phases of fingerprinting and characterization. Proceeding with characterization without making sure that the system is under control is an unnecessary and harmful operation: the result will be a color profile on which prepress operations are set but if these data do not derive from a stable condition, it will be very difficult to expect predictable results.

2nd day

A week goes by and I find myself waiting for a new episode of a television series. The organization is confirmed precise and punctual and I am impatient to see how the fingerprint theme is dealt with, the moment in which the behavior of the printing system is defined numerically: objective values and system variability.

A week goes by and I find myself waiting for a new episode of a television series. The organization is confirmed precise and punctual and I am impatient to see how the fingerprint theme is dealt with, the moment in which the behavior of the printing system is defined numerically: objective values and system variability.

The theme develops around a topic of particularly lively and current interest: the 7-color calibration in extended gamut. The experience comes directly from a wide web flexo printer that told all the stages of the calibration and data acquisition process to define the internal standard and to provide the data necessary for prepress for image separation and color proofing.

The fingerprint phase is fundamental to define the characterization data starting from the 4-color CMYK basic condition. And from these data the profile is obtained, or rather, the profiles necessary for the separation of the images are obtained. Yes, because according to the different needs of the graphic subject to be printed, it is advisable to separate the images with profiles calculated with different black generation. These profiles are then also used for the possible conversion to four-color of spot and Pantone colors and the following presentation illustrated how to optimize these conversions to reduce the total sum of the inks that contribute to the color reproduction, while ensuring a minimum delta E value.

For an effective acquisition of the data describing the behavior of the printing system, it is now possible to use scanning spectrophotometric systems which allow to obtain very useful values on the average and on the variability of the system behavior. A comparison between the off-line and in-line systems provided the public with an interesting analysis of the characteristics, advantages and possibilities of using both systems, with particular attention to the possibility of taking measurements without stopping the machine and providing continuous acquisition some data.

The sessions continued around the color reproduction tolerance and measurement methods with an interesting presentation on the Delta E 2000 accompanied by numerous practical examples.

The sessions continued around the color reproduction tolerance and measurement methods with an interesting presentation on the Delta E 2000 accompanied by numerous practical examples.

The second part of the day, which takes place in America after lunch and takes place after dinner here in Italy, is aimed at the recipients of the calibration and control methods: the print buyers. A panel of experts assisted by a pleasant use of online surveys, in which the public participated in real time, addressed the topics that determine the final customers’ choices regarding the quality of the printed product, from evaluation criteria to expected tolerances.

In all this, the possibility of the printer to be able to declare numerically the values that distinguish the quality level of its production assumes fundamental importance in the eyes of the end customer. The latter today is increasingly prepared on issues related to the psychology of colors but no longer stops at the “normal” quality of the printed product and is increasingly attentive to the aspects relating to the environmental impact that affect the entire life of the product, from design to sales shelf.

3rd day

We arrive at the final day of the Forum, we are at 6 May and the days are now marked by the succession of online meetings and webinars with the most disparate platforms, but at the appointment with the Virtual Forum I arrive prepared and punctual: today we talk about innovation, automation and sustainability.

We arrive at the final day of the Forum, we are at 6 May and the days are now marked by the succession of online meetings and webinars with the most disparate platforms, but at the appointment with the Virtual Forum I arrive prepared and punctual: today we talk about innovation, automation and sustainability.

The opening of the day is entrusted to a roundup on the most significant innovations that have affected the packaging market up to the evolution of industry 4.0, and then to devote attention to the trends that are driving the market towards issues of sustainability and circular economy. In this context, new barrier materials, new mono-material and bio-polymer structures are developed that favor disposal, recovery, re-use and other needs to manage better resources and environmental impact.

Among the innovations that touch the components of flexo printing machine, there is also the possibility of cleaning the anilox rollers with a system that does not use chemicals and does not require significant waste: laser cleaning.

This technology uses laser sources with a wavelength and power different from the lasers used for etching the ceramic and therefore obviously they do not risk damaging the engraved surface of the anilox roller. The environmental impact is truly negligible and significantly better than any other system that uses chemicals, moreover cleaning with the laser has the advantage of being able to remove any trace of the resin contained in the ink that has dried inside the engraved cells, bringing the surface tension of the ceramic back to its original conditions: if the roller has not been subject to wear, abrasions or other damage of mechanical origin, at the end of the laser cleaning it is like having a new anilox roller.

It is then the moment of an intervention that interests me in particular because it deals with a topic of constant criticality for flexo printers: the printing of white ink. The layer of white ink can sometimes be unevenly spread, with pinholes and discrepancies that severely limit the opaque white base function so important in internal printing on transparent film. All this is determined by a balance between the characteristics of anilox roller, ink formulation and transfer characteristics of the plate and can have a considerable impact on the quality of the printed product and on color reproduction. A new holistic and multidimensional method of calculating the “level” of white is proposed which brings together in a single index the opacity, mottle and graininess values and the wish is to have further information on the effective implementation of this measurement method in the short term.

The final sessions of the Virtual Forum 2020 have been entrusted to some students who are lucky enough to attend universities that implement specific courses on flexography and have studied some topical issues such as the accuracy in the reproduction of colors with environmentally friendly inks on substrates biodegradable paper and the variability in the reproduction of special colors on different media. The final session rewarded a project developed by a team of students from California Polytechnic State University on the identity of a brand, from conceptual ideation to positioning, up to the practical development and production of associated packaging. A really well done job, followed with great detail in every detail that bodes well for the future of our industry which will see the participation of prepared young people, capable and attentive to the needs of the brand, the product and the environment.

The final sessions of the Virtual Forum 2020 have been entrusted to some students who are lucky enough to attend universities that implement specific courses on flexography and have studied some topical issues such as the accuracy in the reproduction of colors with environmentally friendly inks on substrates biodegradable paper and the variability in the reproduction of special colors on different media. The final session rewarded a project developed by a team of students from California Polytechnic State University on the identity of a brand, from conceptual ideation to positioning, up to the practical development and production of associated packaging. A really well done job, followed with great detail in every detail that bodes well for the future of our industry which will see the participation of prepared young people, capable and attentive to the needs of the brand, the product and the environment.