TEMAC and SEI LASER: a perfect example of integration between two innovative and complementary technologies

A major customer in the converting industry believed in the advantage of installing an innovative and high-performance laser marking and macro-micro perforation system, like the ones designed and created by SEI LASER, on a TEMAC slitter rewinder machine, and the result has been excellent!

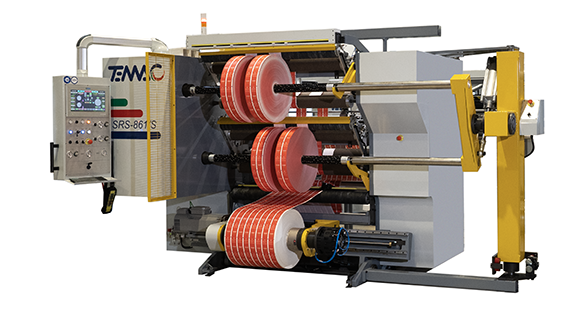

The machine we are talking about is slitter rewinder model SRS 861, a compact machine characterized by a shaftless unwinding cart and two rewinding stations, everything on the front side. SRS 861 joints the extremely compact design of a single-side working station, with the possibility to handle big diameters. This machine can work a great number of flexible materials for many different needs: this feature has been highly appreciated not only by the customer we’re talking about, but also by other users of TEMAC machines.

These slitters are equipped as standard with a control console with an industrial Panel PC IP65 fanless with 15.6” Touch-Screen.

The HMI interface design, based on one of the most powerful SCADA on the market, has been called “PCVISION”: it gathers all the machine’s functions and working parameters with simple, intuitive graphics, contextual help on every touch button, diagnostics offering extensive description and 3D images.

For what external connectivity is concerned, PCVISION allows several possibilities: from web sharing to connection of peripheral devices such as printers, code or RFID readers, images mirroring, additional software installation as MES, ERP, PLM ecc.

All the main hardware devices are linked together on EtherNet backbone, so as to be remotely interrogated or programmed.

The PC VISION interface combined with a real industrial PC makes the machine completely transparent and usable in combination with systems of different origins, as for example marking systems, slitting, perforation, die-cutting and decoration by SEI LASER.

Thanks to this integration readiness, the installation of a laser marking system on the SRS 861 slitter rewinder was successfully carried out: in just one day of work, directly at the customer’s site, all tests were carried out smoothly, to the great satisfaction of the technicians of both companies, present on site to ensure efficient and scrupulous work.

Obviously, the customer was also satisfied with the investment, which proved to be profitable and far-sighted, and will allow him to maximize productivity and have a high- quality finished product.

The added value of the TEMAC – SEI LASER cooperation undoubtedly lies in some key factors: on the one hand, the technical and technological predisposition that makes the machines perfect for integrating with each other, and on the other, the attention to the customer, both as taking charge of initial requests without fear of distorting the products “in the catalog” to meet specific “customization” needs, and as care of the finished work and after-sales assistance.

In addition, the “green” aspect is held in high regard by both companies. As far as TEMAC is concerned, the slitter rewinders meet the requirements of Industry 4.0 and 5.0, since among the more than 700 variables exchanged between the Industrial PC and the customer’s software there may also be those relating to energy consumption. In the machine configuration with 3 or more motors, moreover, the SRS 861 can also contribute to energy saving, since the running motor instead of causing energy dispersion into the environment in the form of heat (as a common axis managed by a brake would do), acts as an energy generator, energy that is then used by the machine itself.

As far as SEI LASER is concerned, the use of laser technology makes it possible to reduce the waste of raw materials and to optimize resources to obtain the best quality while minimizing the environmental impact. Applied to sustainable, renewable and recyclable materials, laser technology makes it possible to obtain an all-round sustainable production process.