From the technological synergy between Saldoflex and Bosch Rexroth comes a truly innovative proposal. LEAF-S8, through an intelligent patented Saldoflex solution based on artificial intelligence and Machine Learning, is able to adjust the set-up of printing pressure automatically and quickly, making the printing process more efficient.

Operating in the sector since 1961, with the historic Filippini & Paganini brand, Saldoflex is one of the world’s leading companies in the production of automatic heat sealers for processing of plastic films and Stack-type flexographic printing machines. Fifty years of experience, combined with an incessant research and development work on new technologies and process optimization, has made it one of the Italian excellences in the production of printing machines: to date, the Lombard company boasts over 2,300 installations in 58 countries worldwide.

An ambitious project: conquering a new market

At the beginning of 2019 Saldoflex, now an established leader in the field of printing and industrial packaging, decides to continue its path of development and innovation by making an ambitious choice: to enter the new high-end packaging and converting market.

At the beginning of 2019 Saldoflex, now an established leader in the field of printing and industrial packaging, decides to continue its path of development and innovation by making an ambitious choice: to enter the new high-end packaging and converting market.

In this way was born the idea of creating a new printing machine capable of competing at the highest level in the field of high quality food packaging.

The project was carried out between 2019 and 2020 in close collaboration with Bosch Rexroth, a reliable and recognized partner in the sector. The design resulted in a highly innovative solution: the new central drum machine called LEAF-S8.

LEAF-S8: AI & Machine Learning algorithm for a smart printing industry

In the flexible packaging market, it is vitally important to increase the standard of print quality and reduce waste and set-up times of the machine. In order to meet these needs and optimize the ways in which the printer interacts with the machine, Saldoflex, in partnership with Bosch Rexroth, has developed LEAF-S8, a newly developed central drum machine that has numerous elements of certain interest for converting market.

Equipped with an innovative solution based on Artificial Intelligence & Machine Learning concepts, LEAF-S8 guarantees a decisive reduction of waste during production. Thanks to artificial intelligence, the proprietary Saldoflex system allows automatic set-up of printing pressures: the process will gain in terms of efficiency and reduction of waste. According to the estimates of Saldoflex experts, this technology allows to reduce at least 10 times the waste of material compared to other solutions currently on the market. It is no coincidence that the name of this new machine is “LEAF”: the symbol of the tree with its leaves and roots recalls the values of long industrial tradition and strong attention to the environment. Elements that guided the company in its design.

Equipped with an innovative solution based on Artificial Intelligence & Machine Learning concepts, LEAF-S8 guarantees a decisive reduction of waste during production. Thanks to artificial intelligence, the proprietary Saldoflex system allows automatic set-up of printing pressures: the process will gain in terms of efficiency and reduction of waste. According to the estimates of Saldoflex experts, this technology allows to reduce at least 10 times the waste of material compared to other solutions currently on the market. It is no coincidence that the name of this new machine is “LEAF”: the symbol of the tree with its leaves and roots recalls the values of long industrial tradition and strong attention to the environment. Elements that guided the company in its design.

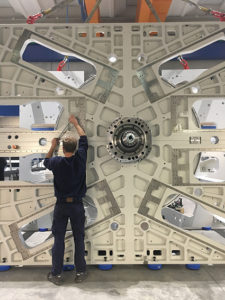

The most compact large format machine on the market

Not only innovative, but also extremely compact. The brand new LEAF-S8 has been designed to meet the most demanding expectations of converting industry: with the central drum diameter of 2270 mm, LEAF-S8 is the most compact large format machine on the market.

Its measures (14.5 m long and 4.5 m wide) guarantee a maximum print width of 1,600 mm and a maximum print development of 1,300 mm.

User experience, connectivity and transparency

Thanks to its advanced level of user experience (totally customizable control dashboard and possibility for the operator to control any parameter through the touch screens positioned in different points of the machine) and a series of convincing technological innovations resulting from FEM analysis conducted internally by Saldoflex R&D team, LEAF-S8 presents itself on the conv erting market as a highly innovative solution. The flexibility and functionality of the new user experience of LEAF-S8 confer significant advantages to the printer: they strengthen productivity, the convenience of management and the timeliness of the intervention which in turn contribute to reduce material waste.

erting market as a highly innovative solution. The flexibility and functionality of the new user experience of LEAF-S8 confer significant advantages to the printer: they strengthen productivity, the convenience of management and the timeliness of the intervention which in turn contribute to reduce material waste.

Speed in job change

In the current market where flexibility and ever shorter runs are required, the speed in changing jobs becomes essential. Saldoflex and Bosch Rexroth have paid great attention to the development of the pneumatic expulsion system and extraction of cliché and anilox to speed up job changeover times, ensuring a high safety standard for operators and maximum prevention of scratches or damage to the sleeves, especially with wide printing widths for large formats.

Bosch Rexroth: cutting-edge solutions in the automation sector

The innovative machine concept of LEAF-S8 has taken shape thanks to the automation solutions guaranteed by Bosch Rexroth, among which the two “brains” IndraMotion MLC” stand out, managing respectively more than 20 print axes and 40 positioning axes of 10 colors, the 530 size torque motor that guarantees precision and fluidity of movement to the large central drum, IndraDrive drives with on-board Safe Motion functions.

“In Saldoflex we found a reality with a solid, structured and future-oriented design approach, capable of entering a mature market such as the central drum flexo with truly innovative ideas and solutions. LEAF-S8 is the result of the introduction of the latest generation of mechanical and IT technologies, combined with “state of the art” solutions by Bosch Rexroth for printing segment. This synergy has allowed the creation of a machine with a clear positioning in the high-end market segment: flexibility, connectivity, compactness and innovation are the characteristics that make it a solution that fully responds to the logic of Industry 4.0”, says Michele Repaci , Segment Manager at Bosch Rexroth.

“We have found a reliable partner in Bosch Rexroth with whom to establish a long-term business relationship. Someone you can count on. Technically prepared, capable of providing advice and the best solution to our specific needs; this specific project, even more than we do already every day, is inspired and reflected in the payoff of our company: ENGINEERED TO PERFORM”, says Marco Filippini, Saldoflex Project Manager & Sales Operations.