The newborn Acimga Gravure Group has produced a beautiful manual, to answer to the needs of professionals to have a valid and useful tool, to let know and appreciate the peculiarities of gravure printing to brand owners, to company marketing, but also to schools, and give gravure the right consideration in the panorama of printing systems

The newborn Acimga Gravure Group has produced a beautiful manual, to answer to the needs of professionals to have a valid and useful tool, to let know and appreciate the peculiarities of gravure printing to brand owners, to company marketing, but also to schools, and give gravure the right consideration in the panorama of printing systems

The Italian school of gravure printing is recognized all over the world, thanks to the work of printers and suppliers of technologies, services and materials, who have exported the quality of their work, both in the publishing and packaging markets. Perhaps the gravure industry in the last few years made the mistake to look at itself a little too much in the mirror, resting on the laurels of an era where this type of printing has become the unchallenged queen of print techniques. The growth of flexo and digital printing in packaging sector has certainly been a stimulus for the drafting of this manual, to which have collaborated primary companies operating in the market, sharing the know-how of their technicians.

The Italian school of gravure printing is recognized all over the world, thanks to the work of printers and suppliers of technologies, services and materials, who have exported the quality of their work, both in the publishing and packaging markets. Perhaps the gravure industry in the last few years made the mistake to look at itself a little too much in the mirror, resting on the laurels of an era where this type of printing has become the unchallenged queen of print techniques. The growth of flexo and digital printing in packaging sector has certainly been a stimulus for the drafting of this manual, to which have collaborated primary companies operating in the market, sharing the know-how of their technicians.

Italian Acimga Gravure Group

“Acimga has taken up the challenge launched by Mario and Gianmatteo Maggioni (ICR), creating a working table to carry out this manual on gravure technology, to promote the value of this technology, which has important numbers regarding the reference applications with unique industrial yields”, begins Andrea Briganti, Acimga director, underlining how this manual is only the first step of a work that will certainly have future developments.

“Acimga has taken up the challenge launched by Mario and Gianmatteo Maggioni (ICR), creating a working table to carry out this manual on gravure technology, to promote the value of this technology, which has important numbers regarding the reference applications with unique industrial yields”, begins Andrea Briganti, Acimga director, underlining how this manual is only the first step of a work that will certainly have future developments.

Italian Acimga Gravure Group, after this first experience, decided to structure itself into subgroups to deal with regulatory aspects, training with collaborations with schools, companies and associations (ERA, the European gravure association that has a beautiful demo center in Stuttgart with a BOBST gravure machine), and a last subgroup that will deepen the various chapters of the first manual. Promotion and marketing activities are also being studied with conferences aimed at printers, technology suppliers and brand owners.

The manual: gravure told by those who are using it every day

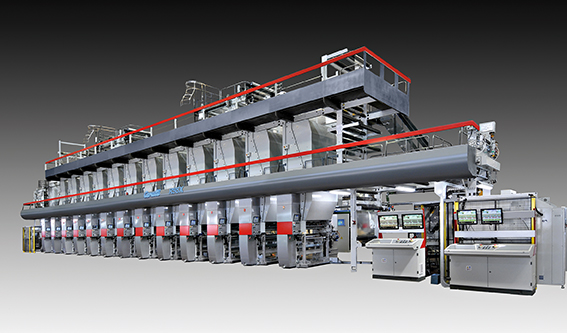

Gravure printing is a technology that combines a particularly high print quality with an excellent ratio between price and printed meter that, on long runs, knows no rivals. In about one hundred pages, the publication illustrates all aspects, highlighting the applications and including a practical glossary at the end. From historical notes to workflow, from color to inks and coatings, through pre-press and cylinder engraving and, of course, components such as doctor blades and pressure rollers. The text, printed in English and Italian, is a multi-hand work, where some of the leading experts in the field have shared their experience for a popularizing and promotion initiative of gravure technology.

Gravure printing is a technology that combines a particularly high print quality with an excellent ratio between price and printed meter that, on long runs, knows no rivals. In about one hundred pages, the publication illustrates all aspects, highlighting the applications and including a practical glossary at the end. From historical notes to workflow, from color to inks and coatings, through pre-press and cylinder engraving and, of course, components such as doctor blades and pressure rollers. The text, printed in English and Italian, is a multi-hand work, where some of the leading experts in the field have shared their experience for a popularizing and promotion initiative of gravure technology.

The text, in addition to the chapter written by Gianmatteo Maggioni (Printing cylinders), includes the work of Giovanni Daprà (Introduction, historical background, process and prepress), Carlo Carnelli (Color), Giuseppe Gianetti (Inks), Angelo Alloggia (Pressure rollers) and Sergio Santarlasci (Doctor blade).

“Italy has a great tradition and extensive know-how in gravure technology, – explains the coordinator of the manual Gianmatteo Maggioni – not only in the construction of the machines, but also in cylinders engraving and in the production of components. So far all this was known only in the circle of insiders or a little more. Sharing this knowledge means restoring the role of gravure among printing, converting and packaging technologies. We are the second European country as regards gravure printing plants, behind Germany and for the number of printing machines installed with regards to flexible packaging market and decorative printing”.

The importance of training: network of associations, companies and schools

During the presentation of the manual, the aspect that emerged predominantly with the interventions of the experts who collaborated in its drafting was the lack of training starting from the graphic schools, an element which led them to include in the various chapters also some basic notions essential to better understand not only gravure printing but more generally the printing industry, which was once defined as graphic arts. Training and therefore a relationship of collaboration with schools is one of the main objectives of this project and it is also the reason why the working group deliberately chose to prepare a simple text, easy to understand and with basic notions; it is necessary to excite young students and encourage them to deepen their knowledge of this printing technique, also and especially in relation to applications, with a better support of companies to schools, an availability that has been confirmed by the participants of Acimga Gravure Working Group . “This is the starting point of a path that we want to pursue together with all the operators in the supply chain, from schools to companies, including brand owners and end users”, concludes Gianmatteo Maggioni.

During the presentation of the manual, the aspect that emerged predominantly with the interventions of the experts who collaborated in its drafting was the lack of training starting from the graphic schools, an element which led them to include in the various chapters also some basic notions essential to better understand not only gravure printing but more generally the printing industry, which was once defined as graphic arts. Training and therefore a relationship of collaboration with schools is one of the main objectives of this project and it is also the reason why the working group deliberately chose to prepare a simple text, easy to understand and with basic notions; it is necessary to excite young students and encourage them to deepen their knowledge of this printing technique, also and especially in relation to applications, with a better support of companies to schools, an availability that has been confirmed by the participants of Acimga Gravure Working Group . “This is the starting point of a path that we want to pursue together with all the operators in the supply chain, from schools to companies, including brand owners and end users”, concludes Gianmatteo Maggioni.

Face to face with Andrea Briganti, Director of Acimga

Face to face with Andrea Briganti, Director of Acimga

In light of growing of hybrid market, wouldn’t it be appropriate to sit all around the same table and face the pros and cons of various technologies in the combined printing process?

“As a trade association we represent all printing technologies and we are aware of the increasingly hybrid direction of the market. But the group is born from a specific need: brand owners and printers know little about the advantages and applications of gravure. In this context it becomes difficult for a printer, for example, to choose a hybrid machine with a gravure unit, simply because he does not have in mind what is the plus offered by this technology is. Our task as an association is speaking about all the solutions that Italian machine manufacturers can offer to the supply chain. Therefore, gravure group does not detract anything from other technologies. And it is no coincidence that we have recently signed an agreement with Atif, the technical flexo association, precisely to create positive synergies for our members, increasing training and awareness about all the printing technologies offered by Italian manufacturers”.

Can you explain better how you intend to deal with ERA and what initiatives are you considering?

Can you explain better how you intend to deal with ERA and what initiatives are you considering?

“The English translation of the manual will be printed shortly. As soon as this version is ready, we will set up a meeting with ERA’s top management to illustrate our project and to organize common initiatives not only for communication, but above all for training. An Italian gap that the group wants to fill is exactly this: our local gravure machines manufacturers were not present at international associations meetings. Not by chance, one of the first initiatives of the rotogravure group was to delegate a member (Carlo Carnelli) as a representative at ISO (International Organization for Standardization)”.

What are the requirements to be able to join the next working groups and what is the procedure to get a a copy of the manual?

What are the requirements to be able to join the next working groups and what is the procedure to get a a copy of the manual?

“The gravure group and work subgroups (for the annual event, training and further editorial initiatives) are open to all Acimga members and participation is strongly recommended. Obviously, our aim is to collect and involve as many companies as possible, so we have created very favorable conditions for those wishing to join the group, but not yet an Acimga member. Our secretariat is available to illustrate how to join the association. As far as the manual is concerned, individual copies have already been sent free of charge to the associations and training institutions that requested them. So there is no price for the book. Our association, it is always important to repeat it, does not aim at profit. Our aim is to create the best conditions for Italian companies to express themselves, making the sector grow in this way”.