The SEI PaperOne 5000 supplied by Tripa Converting Solutions breaks open new markets for Yart Factory

Yart Factory in Waalwijk (The Netherlands) specialises in laser cutting. The company excels in unique paper productions. It also works for sister company Point to Paper and relies on the SEI laser cutting machines, supplied by Tripa Converting Solutions.

Yart Factory in Waalwijk (The Netherlands) specialises in laser cutting. The company excels in unique paper productions. It also works for sister company Point to Paper and relies on the SEI laser cutting machines, supplied by Tripa Converting Solutions.

Yart Factory was the first-ever company worldwide to install the SEI PaperOne 5000, a machine that handles digital die-cutting and creasing of B2 size sheets.

Complex

“Complex production has become our thing, it seems,” Joep Hoffmans, owner of Yart Factory and Point to Paper states. “The beauty of it all is that it makes it harder for others to imitate, let alone emulate.”

The showroom is filled to the brim with intricate cutouts in paper, plastic, wood, and leather. Post-finishing of paper happens under the Point to Paper umbrella, a household name and activity at many graphic tradeshows.

The common thread

Yart Factory has been around for 65 years. Joep’s father started in the leather manufacturing business in 1954. At that time, Waalwijk was the beating heart of the shoe market. Profitable niche markets like belts inspired him to die-cut his clothing accessories. “Die-cutting has always been a common thread in our company,” Joep adds. “We always turned substrates into shapes.” It led them to create hobby market products. The rise of the Chinese competition made them switch direction towards the graphics industry, under the Point to Paper name.

Die-cutting on the fly

The factory sits within Yart Factory. The company produces for the graphics industry, and also the hobby market and the growing home decor market.

A shining example is a tabletop with the laser engraved company logo.

The SEI PaperOne 5000 takes up a prominent position in the factory. The PaperOne 5000 is the perfect machine for the “on the fly” digital laser die-cutting of brochures, commercial print, and folding carton packaging. This implies that the laser cutting happens during the transport of the printed sheets, without the need to stop the transport. It’s also possible to mechanical crease the material for folding carton boxes or presentation folders. It enables the production of small to medium-sized batches at the minimum of staff intervention.

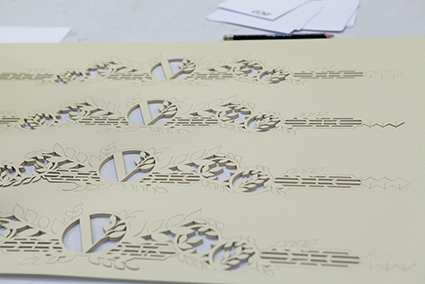

The PaperOne not only entirely replaces traditional die-cutting, but the laser also applies intricate details onto the material. By using a four-axis galvo technique, it is possible to achieve an extremely small laser spot on every inch of the operating field at the highest quality.

Add value

Add value

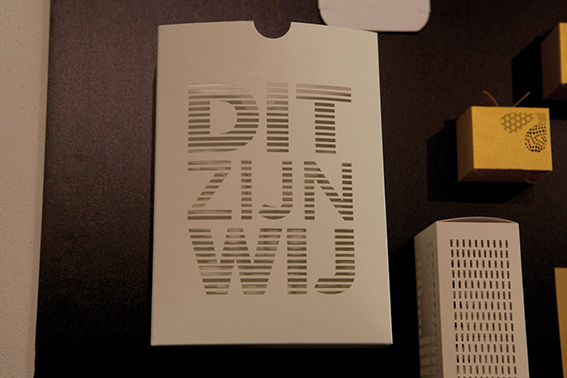

“The business side of commercial print is going really well,” Joep comments. Also, the packaging market opens up exciting opportunities for the company. Point of Paper creates special boxes for the cosmetics industry. The SEI PaperOne die-cuts and creases these boxes from carton B2 sheets up to 700 grams.

That’s how Yart adds value to the packaging and how it counterfeits falsifications. A perfect example is the Armani perfume card that delivers a unique experience thanks to laser die-cutting. The die-cut shape is very detailed. “Hardly anyone can pull this off.” Joep states. “No more brown edges.” Richard de Bruijn of Tripa Converting Solutions adds: “It’s all thanks to the fineness of the laser cutting beam. If it’s very thin, you don’t need to remove that much material, and you hardly get any burns. SEI develops all laser systems in house and possesses unfathomable laser knowhow. Years of R&D expertise is how they outsmart the competition. At Drupa next year SEI will introduce a machine that can handle sheets twice the size. That’s B1, 70 x 100 cm”.

Top-notch quality

Some pretty impressive names rely on the Yart Factory production. Joep: “We collaborate with high-quality printers in Paris. France is a vital market for us. Big brands have come to rely on our quality to create something truly unique. That’s because we’ve been exploring the borders of feasibility for years. That’s how we achieve perfection in all that we create.

Joep owes it to the smart combination of suitable machines and building years of knowhow. “Nothing is standard here; everything is special and a challenge on its own.” Like the three-dimensional Christmas card sent out by paper producer Iggesund. Also a Yart Factory realization.

The search

The search

Supplying the right file is a job on its own. “It’s one of our biggest challenges. It’s a different thing to prepare a print-ready file than it is to prepare a file for a detailed die-cut shape.”

Yart Factory and Point to Paper deliver to printing houses all over Europe. They work with agents in most countries. To deliver the quality most customers demand, the supplier of the laser cutting systems must deliver both outstanding laser cutting systems and the accompanying optimal service. SEI Laser and Tripa Converting Solutions deliver this combination and meets the high standards.

“Our drive to keep on innovating, boosts our continuous exploration of possibilities, challenges, and markets.