Operating since 1971 in the flexible packaging market, the Sit Group has been relying on the company Bimec S.r.l. for more than 25 years for the supply of high quality slitter rewinders.

Operating since 1971 in the flexible packaging market, the Sit Group has been relying on the company Bimec S.r.l. for more than 25 years for the supply of high quality slitter rewinders.

SIT Group is one of Europe’s leaders in packaging converting for different fields, in particular the food industry, and counts 47 Bimec machines in action in its four production sites (San Marino, Pesaro, Padua and Crema): ranging from the previous STM50 models, to the latest generation duplex slitters of the TF60 ‘single-face’ series, the TCA 64C+ duplex turret slitter rewinder models and the ancillary equipments, such as the BDM and BDM-L reversible rewinders and the TMA automatic core cutters.

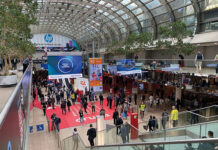

The most recent supply concerns a BDM-L reversible salvage rewinder destined for the facility in Pesaro, two TCA64C+ duplex turret slitter rewinders, a BDM reversible rewinder and a TMA automatic core cutter, destined for the historic Faetano – San Marino facility, which last September hosted a double inauguration: the new printing plant and the renovated and extended slitting site, as well as an entire department dedicated to R&D, the brand new SIT Innovation Centre.

These five machines were installed in the last months of 2022 by Bimec specialised personnel and are working at full capacity, to the great satisfaction of the San Marino group.

The two TCA 64C+ duplex turret slitter rewinders are equipped with a semi-integrated unwinding carriage, which allows easy access to the slitting area, facilitating the set-up operations and preventing the risk of material contamination.

They are designed for razor blades and pneumatic circular knives slitting and count several automatisms, including the automatic positioning system of the knife holders and multi-groove female knives, which are combined with the automatic single laser beam for core positioning and a reel unloading station, which allows the automatic opening/closing and rotation of the side stand arms.

These automatisms enhance the company capacity and productivity, drastically reducing machine downtimes while facilitating the operator’s work at the same time.

Bimec has equipped the slitters with non-stick rollers, which are also suitable for processing coated materials with “cold seal” and has manufactured the machines in a specular configuration to facilitate the operator’s work when unloading and packing the finished reels.

The TCA64C+ models unwind mother rolls with a diameter up to 1000 mm, rewinds finished rolls with a diameter up to 610 mm and reaches a maximum speed of 800 m/min, allowing a quick loading and unloading of the finished rolls thanks to the automatisms of the machine.

The reversible rewinders of the BDM series are designed for the inspection and cleaning of jumbo rolls with printing, extrusion or inclusion defects. They unwind and rewind rolls with a maximum diameter of 1000 mm and reach a maximum speed of 600 m/min. The equipments include a bi-directional rewinding system, which allows the reel to be returned to its original condition.

The TMA automatic core cutter, on the other hand, was supplied to cut cardboard cores with various inside diameters cores, from 70 to 152 mm. The machine is equipped with an automatic core loader, which is synchronised with the core cutter for the cores’ feeding and cutting.

A user-friendly touch-screen operator panel allows to set quickly and easily up to seven different widths on the same core in optimisation mode and automatically calculates the smallest possible waste.

In addition, it allows for the cutting of shorter sizes to be unloaded by gravity into a special container, and for longer sizes on an inclined table.

“We are honoured to be a partner of a large group like SIT, which has always stood out for the quality of its products, continuous innovation and professionalism. But what makes us most proud is the long-standing relationship of cooperation and mutual trust that we have established over the last 25 years, meeting their production needs with the models of our range.” declares Eng. Davide Bottoli, Bimec General Manager.