In the cardboard packaging industry, production and logistics are often perceived as the true drivers of competitiveness; this is precisely where efficiency and optimization come into play. Those who delve deeper, however, understand that there’s a process upstream that serves as a true strategic lever for the company’s success: the planning and estimating phase.

By Jan Jürgen Bredereck, Marco Brisotto

Email: marketing@induvation.com o bredereck@induvation.com

This is where it’s decided whether a company will be able to respond quickly to the market, ensure sustainable margins, and build valuable relationships with customers. Furthermore, this process lays the foundation for efficient operational execution: the magic word, in this case, is “industrialization.”

At this stage, it’s essential to be able to answer some crucial questions:

- Do I have all the information necessary to develop a consistent estimating?

- Is it possible to meet the customer’s quality requirements while respecting the minimum company margin defined for the completion of the order?

- Do I know how saturated my technical department is, based on the timeframes of the activities associated with this process?

From our experience, we can assure you that, most of the time, cardboard companies answer negatively to these questions. It should also be added that, as evidenced by surveys conducted among our clients, efficient and effective planning services are among the most important critical competitive factors in the cardboard industry.

So, how can we make the planning and estimating process more efficient while maintaining effectiveness for the customer?

The problem: systemic inefficiencies that erode margins

First of all, it must be stated that the variety of estimating and planning processes within a cardboard company depends on the level of service they want to offer customers. The higher the standard, the more complex the process.

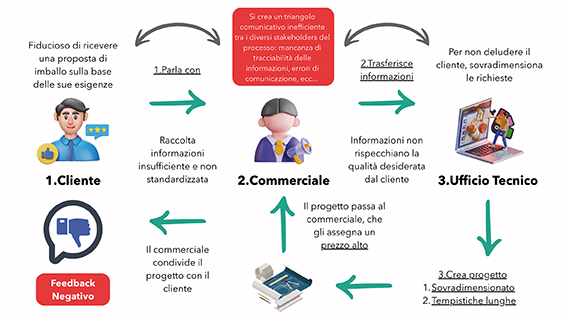

Many box factories and converting companies experience the same challenges:

- Fragmented information between sales and technical departments, leading to misinterpretations, e-mail exchanges, and endless iterations.

- Oversized proposals, often designed to protect oneself, but which actually increase costs and reduce margins.

- Long response times, with the risk of losing business opportunities in favor of faster competitors.

- Lack of key indicators, which obscures bottlenecks and impedes process improvement. Here are some key indicators for best managing the process:o Level of saturation of the technical department

o Processing times for specific order groups

o Processing times for previous processes or related to planning and estimating (time needed for the supplier to create the die-cut quote, for example)

The result? It often translates into compromised margins already at estimating stage, orders managed with haste and customers who perceive slowness and disorganization, as well as a lack of analysis regarding product industrialization.

Not surprisingly, in many cases the problem lies not in production (where all the errors caused by previous processes must be managed), but in the decision-making and organizational funnel of estimating.

The solution: standardize and digitize the process

To reverse this trend, a change in approach is needed: treating planning and estimating as a structured, standardized, and measurable process, with known and defined activities and timelines, rather than as an improvised activity that depends on the type of customer request.

The key actions to achieve this goal are the following:

- Standardization of information inputs and outputs: each order must be described with clear and consistent data. No vague requests: predefined forms and formats eliminate ambiguity and reduce errors, and above all, they act as a bridge between two worlds with often different objectives: the sales department and the technical department.

- Defined responsibilities and defined processes: establish who does what, when, and how within the planning and estimating process. Flowcharts and checklists (to be used, for example, when the sales representative requests packaging information from the customer) allow to visualize the critical steps.

- Involvement of external partners: suppliers of equipment, dies, and systems, as well as external production service providers, must be included in the information flow, reducing coordination times and preventing planning errors.

- Capacity of the technical department: like a production department, the technical department also has load limits. Recognizing them means avoiding bottlenecks and methodically managing priorities, as well as providing the end customer with an accurate estimating date (increasing the level of service). For this reason, knowing the internal lead times of related sub-processes is essential. The greatest impact on estimating lead times is generated by waiting times, rather than operating times (especially when waiting for information from an external function over which you have no control).

- Integration of additional services: additional logistics services, such as warehouse storage, multiple deliveries, special packaging, and emergency management, involve significant costs and must therefore be considered and integrated during the estimating and planning phase.

- Integrate industrialization aspects into planning: defining the quality of equipment suited to production performance and product quality, product standardization (e.g., corrugator papers and composition), with the aim of increasing corrugator performance and promoting the development of product types that are consistent with the characteristics of the company’s machinery.

- Technical department expertise: In our experience, the technical department is often overlooked in aspects related to the production of cardboard packaging and is unaware of the key factors that influence product performance. Active training of the technical department, combined with a constant presence on site, increases product quality and customer satisfaction.

The digital turn

Once the process is stable, digitalization becomes the natural progression. Here are two hints that, in our opinion, would be beneficial to integrate into the process:

- Workflow Management System to automatically manage versions, attachments, deadlines, and notifications, within a process that combines different company functions and also involves external suppliers, who influence process timelines.

- Process Mining to map actual flows, identify inefficiencies, and propose data-driven improvements.

More advanced tools, such as CPQ (Configure, Price, Quote) software, allow to generate accurate and consistent quotes in minutes, integrating technical and commercial rules into a single platform.

Tools like CPQ, integrated with the company CRM, allow to process estimatings directly, ensuring that salespeople cannot propose unfeasible configurations or inconsistent prices. This prevents minimum margin issues, as well as potential order production issues.

A real game changer we’ve frequently encountered in projects with our clients is the ability for salespeople, including external ones, to remotely enter information during customer or prospect visits directly in digital format on their phone or tablet and, in the most favorable cases (at least for simple estimates), process the sale price in real time.

Other companies, however, have adopted integrated CAD + management solutions: the technical project drawn in the software is automatically transferred to the estimating system, which generates technical sheets and cost calculations in real time. A key aspect in this context, for more complex projects, is the use of parametric drawings.

This dramatically reduces time and increases the number of estimates produced, without the need to introduce new resources into the process.

The benefits: greater efficiency, higher margins, greater value for customer

Implementing a standardized and digital estimating process is a concrete investment that yields measurable results. It’s very important to keep in mind that the digitalization phase must always follow the process standardization phase: this applies to all business processes, as it’s easier to digitize standard procedures than an undefined management.

Here are some benefits of standardizing and subsequently digitizing the planning and estimating process:

• Reduced response times: estimating can go from days to a few hours. Some software, for example, reduces this time by up to 95%.

• Greater accuracy of offers: consistent technical proposals, without overestimations that erode margins and jeopardize the quality of the order.

• Traceability and transparency: each step is documented, reducing errors, misunderstandings, and responsability.

• Data for sales strategy: indicators on time, costs, and causes of lost offers, useful for guiding market decisions and continuous improvement.

• Customer perceived value: a partner that responds quickly and reliably becomes the first choice when it comes to switching suppliers.

Centralizing this crucial process eliminates manual steps, reduces errors, and improves internal communication. A company that manages estimates well not only improves internal efficiency but also builds trust externally. And trust, in the cardboard packaging market, translates into lasting relationships, higher margins, and market leadership.

The vision: from process to competitive advantage

In a mature market like the cardboard packaging one, differentiation can no longer be based solely on price or generic flexibility, as we have already emphasized in previous articles.

The real challenge is to transform planning and estimation into a strategic lever to:

- Support profitable growth.

- Align commercial promises with actual internal capabilities.

- Free up resources from repetitive tasks to focus on innovation and customer service.

Those who standardize and digitize today lay the foundation for sustainable competitiveness tomorrow. The future of cardboard packaging will hinge on the ability to combine speed, precision, and margins. And all of this also begins in the planning and estimating phase: the brains of the company.