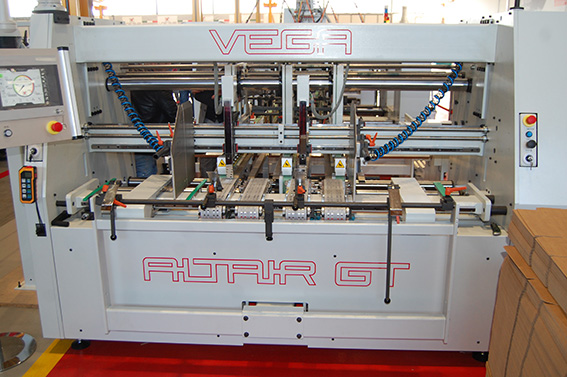

On March 12-13-14, Vega, the historic manufacturer of folder-gluer machines based in Paderno Dugnano (MI) opened the doors of its plant to show the new automatic line for corrugated cardboard consisting of the brand new Altair GT 200 folder-gluer machine plus the complementary machines Vega Easypack and Vega Rotopack, integrated with the SMB COR strapping machine from Signode.

There was a great turnout for this event, about 80 customers arrived from all over Europe to participate in the open house which represents the first of several “missions” of the Vega Program 2024.

During these three days, it was possible to test and observe the functionality of this automatic line, also with different boxes changeovers, which not only reduces the number of operators on board machine, but also facilitates the operator’s work.

The Vega team, consisting of President Jacopo Nava, Managing Director Marco Giovannini and Sales Director Remo Paiola, together with the technical team, accompanied customers through each step of the line.

It starts with the Altair GT folder-gluer, on this occasion size 200, the flagship among the Vega machines, equipped with a new look and several technological innovations including motorised gauges in the feeding section, computerised gluing guns, which allow precision and changeover time savings, and a “gap control” camera which allows automatic control of any fish-tail effect of the boxes. The latter, together with four other quality control systems, also allows the extraction of non-conforming boxes through the optional ‘extractor’ module, without interrupting the line. In addition to this last optional module, the Altair GT model tested during the open house is also equipped with other optional modules including the high speed 4/6 corner and pressure rollers and the fully computerised exit.

The exhibited line continues in the automatic collection section composed of the Vega Easypack, which counts and separates the shingled boxes directly from the folder gluer pressure belt, creating semi-parcels of boxes ready to be palletised by the Vega Rotopack, a one-of-a-kind module that rotates, flips or overlaps each single bundle, and prepares it for the best palletization process.

Closing the end of the line is the SMB COR strapping machine from Signode, one of the most efficient and variable strapping machines for folded boxes, also equipped with state-of-the-art technical features that allow precision and complete automation of the production process.

President Jacopo Nava, closed this event as follows: “I would like to thank all the customers, suppliers and friends who took part in our event, I am very satisfied with the turnout and the performance of the line we presented. We also received a lot of enquiries from big companies in the packaging sector, which we hope will turn into new collaborations”. The President confirms Vega’s growth also in the North American market, thanks also to the close collaboration with its partner Stitching & Gluing Solutions, which will soon open a showroom in the U.S. dedicated entirely to Vega products.

Managing Director Marco Giovannini also states that: “the industry’s propensity to automate the production process goes hand in hand with the technological boost given by Vega in recent years to its product, which step by step is becoming a benchmark in the sector. We are proud of what we are doing through the passionate work of a team of professionals dedicated to improving the folding machine in every aspect while constantly listening to the user.”

The ‘Vega Program 2024’ continues, the launch of the next mission is towards Drupa 2024.