Diaven celebrated 40 years of activity last May. Unfortunately, the idea of Nicoletti family, owner of the company, to celebrate the event with customers, suppliers and friends who have accompanied the growth of this service over the years, has not been able to materialize because of the restrictions.

In addition to creating the well-known inconveniences, Covid emergency has also hampered the usual celebrations that companies usually organize to remember the milestones of their history. This is the case of Diaven, who celebrated 40 years of activity last May, deciding to celebrate the birthday with his collaborators in the family, a sign of attention and thanks to those who have made an important contribution to corporate success.

“It was an afternoon spent together sharing also not-working experiences and taking the time to get to know each other better to strengthen the sense of belonging and mutual knowledge. The result was an intimate party where everyone participated with joy between memories and plans for the future”, says Giuliano Nicoletti, founder of the company.

We retrace these 40 years in the world of flexography with Filippo Nicoletti, owner and director of business processes and Cristian Zanella, Area Sales Manager.

Face to face with Filippo Nicoletti (FP) and Cristian Zanella (CZ)

FN – How important is the experience in the prepress sector and what makes your work unique?

“In 40 years we have followed all the evolution and growth of flexography. We are in a sector where the choice of technologies and the level of customer service are decisive for the growth of the company, so we think that the experience in prepress is evident today in Diaven’s structure and concreteness. We have been able to interpret market trends, both from a commercial and technological point of view, to anticipate future trends while remaining faithful to values such as professionalism and ethics. This allows us to make investments both on a production and professional level to respond to customer needs”.

CZ – Every company has a mission, what is Diaven’s mission?

“Our mission was the result of an analysis of our skills and values that led us to claim to be the right partner for companies that recognize the value of image, communication and functionality in packaging. We strive every day to ensure that our customers get maximum expressiveness from the packaging because we know how this is important for the sale to the end customer. To obtain this result we apply a tailored 4.0 automation that combines the advantages of an automated and lean production (functionality) with a service and a ‘tailor-made’ customer relationship that takes into account the specific needs of each.

To this we add particular attention to the well-being of our staff because the people who contribute every day to the satisfaction of our customers must have the opportunity to be recognized as leaders in their respective roles. Half of our time is spent in the workplace and it is important that the working day is lived positively”.

FN – In recent years, you made many investments to innovate your production process, which have been the most important and what are the benefits for production?

“The investments made in recent years have focused on digitalization and automation with the aim of obtaining data security and therefore greater process control.

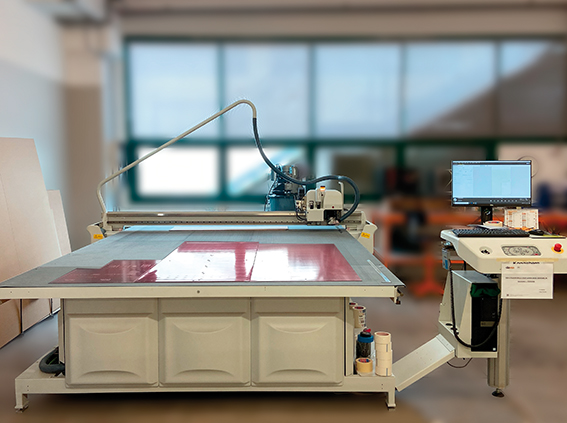

Real-time information is essential for us and responds directly to the customer’s need to be informed and to acquire our service as an integral part of printing. In this way, we were able to lengthen the processing times, which went from 8 to 12/13 hours a day, guaranteeing quicker responses and a production schedule that adhered to customer needs. Among the most significant innovations we can mention Esko CDI Crystal 5080 unit, VIANORD EASY TO PLATE ™ TWO modular production line and Esko Kongsberg i-XL Series plotter.

In addition to commercial purposes, the system has added professionalism to our employees by qualifying the work on the machine in supervising the process, and has allowed safer and greener production management thanks to the intelligent management of the solvent during the processing phase”.

CZ – Diaven places great emphasis on quality in all aspects of its service. What services do customers appreciate most?

“The flexographic prepress department was born as an artisan service for printers and gradually over time has become an automated service. Technology has replaced many of the tasks previously entrusted to operators, but at the same time the demand for planning, consultancy and after-sales has increased thanks to the increasing complexity of the processes. The planning during the order phase is certainly is very important for Diaven, because it is in this phase that experience and knowledge allow the achievement of the optimal printing result through a process that we can define as problem solving. In this phase it is possible, in collaboration with the customer, to find efficient and effective printing solutions that allow instant printing.

In sales assistance, the customer finds every day availability, competence and speed of response aimed at ensuring the expected final result”.

FN – Partnership with the customer is a hot topic. For you what does the partnership with the printer consist of?

“Partnership for us means sharing the data provided by the flexo printing to obtain the parameters of the customer’s printing process to be able to control the result. We say, therefore, “sure of the result” not as a slogan, but to indicate a quality process that aims to maximize print yield.

“Partnership for us means sharing the data provided by the flexo printing to obtain the parameters of the customer’s printing process to be able to control the result. We say, therefore, “sure of the result” not as a slogan, but to indicate a quality process that aims to maximize print yield.

The partnership with our customers is also a tool to be more performing together on the market for the benefit of the buyers. We exchange information and growth targets with printers in order to collaborate to be more competitive together. Often our printing customers put us in direct contact with their customers so that we can provide a service and technical advice aimed at satisfying their needs in the best possible way, from graphics to supervision during printing”.

FN – Graphics ability is very important in the prepress industry. How do you stand out on the market?

“Graphics are an expression of creativity, but it is also a technical project for the production process. Sometimes it happens that creativity and production don’t speak the same language. An interpretation of the project is therefore required that ensures maximum yield while maintaining the communication objective of the packaging. Our graphic designers are able to understand the customer’s image needs by adapting them to the printing process without taking anything away from creativity. In addition, when the situation requires it, we are ready to provide a service that we have called Plug & Play because it provides for the accompaniment of the customer up to printing to guarantee a total result security”.

FN – There is more and more talk about lean production, how are you organized internally to guarantee a lean process?

“The search for efficiency both at production and organizational level has been one of the main objectives in the past two years. We have optimized our warehouse and production thanks to the analysis of As Is and the introduction of the “Spaghetti Chart” to optimize the lay out and eliminate waste. We are also equipped with integrated software between ERP, warehouse and CRM that allow us to have a database to draw on for real-time analysis of production, costs and sales in order to optimize management according to the market. We recently started to introduce the 5-S methodology in the company to further streamline business processes and clean the workplace to improve performance”.

“The search for efficiency both at production and organizational level has been one of the main objectives in the past two years. We have optimized our warehouse and production thanks to the analysis of As Is and the introduction of the “Spaghetti Chart” to optimize the lay out and eliminate waste. We are also equipped with integrated software between ERP, warehouse and CRM that allow us to have a database to draw on for real-time analysis of production, costs and sales in order to optimize management according to the market. We recently started to introduce the 5-S methodology in the company to further streamline business processes and clean the workplace to improve performance”.

CZ – Your 2019 was very positive for you. What were the contributing factors?

“The positive results of 2019 are the consequence of the work done internally in previous years. The investments made both in technology and in staff enhancement have allowed us to retain our customers and acquire new ones. Even in this moment of objective difficulty for everyone, we are optimistic because we continue to see the fruit of our commitment”.

FN – What predictions do you have for your market and what plans for the future?

“Market forecasts are not easy in this post-Covid moment. We hope that the crisis is only the result of the exceptional nature of the moment and will not continue over time. We already see some small signs of recovery and there are certainly sectors that have been favored by the emergency such as food and pharmaceuticals. We currently plan to return to the growth trend that we recorded in the first three months of the year by September. For the future, we plan to maintain the growth trend and consolidate our position on the market”.