In Caravaggio, the professional maintenance of die-cutters to prolong the life of the tool and to optimise costs for die-cutter industries

On 21 June in Serviform’s “Spazio Next”, the second Module of ServiForma – Die-cutting techniques from A to Z captured the attention of the 30 participants from the very beginning of the course. The die-cutter has never been the focus of so much attention. Blades, rubbers, incisions and maintenance were the focus points of the day, which once again also dedicated significant time to the exchange of knowledge.

On 21 June in Serviform’s “Spazio Next”, the second Module of ServiForma – Die-cutting techniques from A to Z captured the attention of the 30 participants from the very beginning of the course. The die-cutter has never been the focus of so much attention. Blades, rubbers, incisions and maintenance were the focus points of the day, which once again also dedicated significant time to the exchange of knowledge.

Perfect rubber coating is anything but a foregone conclusion, particularly if the die-cutter has already performed a certain number of impacts. How to prevent serious consequences in terms of die-cut quality and functioning of the die-cutter itself, due to an incorrect or poorly executed rubber coating? Pablo Bogado, the most experienced speaker in the training programme, showed a series of examples of correct and incorrect rubber coating, presenting practical solutions for the creation of complex shapes in a clear manner. Paolo Fedrighi, Serviform’s materials manager, explained the advantages and disadvantages of using open-cell or closed-cell rubbers, and examined in detail the use of cutting and creasing profiles.

The choice of the cutting blades for the die-cutter is generally part of the responsibility of die-cutter manufacturers from which the majority of die-cutter industries commission the production of this tool. Considering that the choice of blade has a direct effect on the quality of the work carried out by die makers, it is fundamental to be able to identify the different types of blade available and be aware of their properties, both at the beginning of use and during operations. Beginning with the properties of the raw material – steel – and then examining its processing, the participants were given hands-on experience of the various steel blades produced by Martin Miller, currently considered to be among the best on the market.

The choice of the cutting blades for the die-cutter is generally part of the responsibility of die-cutter manufacturers from which the majority of die-cutter industries commission the production of this tool. Considering that the choice of blade has a direct effect on the quality of the work carried out by die makers, it is fundamental to be able to identify the different types of blade available and be aware of their properties, both at the beginning of use and during operations. Beginning with the properties of the raw material – steel – and then examining its processing, the participants were given hands-on experience of the various steel blades produced by Martin Miller, currently considered to be among the best on the market.

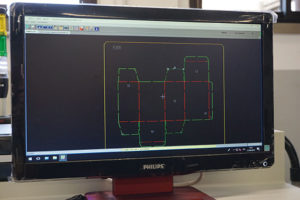

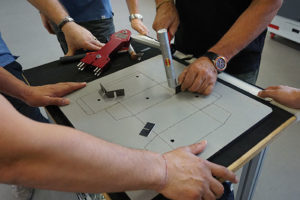

Andrea Savoia, a member of Serviform’s technical sales staff, then presented a practical exercise regarding the ideal combination of wood, blade and rubber, with the aim of enabling the participants to order the die-cutter best suited to their products to be cut.

How to create die-cuts with as few incisions as possible, thus responding to the majority of client requests? This was one of the main subjects of Module II of ServiForma. A whole hour of discussion allowed the participants to provide real examples illustrating the day-to-day problems regarding incisions, while Bogado skilfully illustrated that eliminating them completely is impossible. He did however show where to position them and what kind of incision to use in order to optimise production without limiting quality. A series of practical examples helped to consolidate the theory studied and allowed it to be immediately applied in the respective companies.

The proper maintenance of the die-cutters being used by die-cutter industries is one of the themes of major interest to the participants of the course, as the majority of them are involved in this delicate task.

The proper maintenance of the die-cutters being used by die-cutter industries is one of the themes of major interest to the participants of the course, as the majority of them are involved in this delicate task.

Any repairs and ordinary maintenance operations for the equipment can readily be performed directly by the die-cutting personnel themselves. A fundamental condition is that they use suitable instruments and materials, and that dedicated operations are carried out in the right place, dedicating the appropriate amount of time.

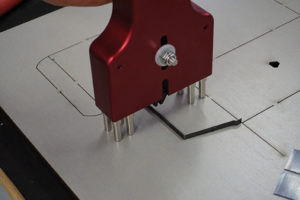

In this context, Franco Roglio, a die-cutter veteran, illustrated the functioning of the Serviform EcoPlus, Serviform’s automatic bender, which unites the traditional bending system with an innovative pre-cutting and final shear cutting system. With this machine, created by Serviform for die-cutter manufacturers, participants were able to follow the production of the cutting rules from beginning to end, including their fitting onto a test die-cutter. It was a very useful moment that offered an opportunity to meet an experienced die-cutter fitter, who was able to explain and demonstrate different bending and fitting techniques and the relative maintenance of the materials.

In this context, Franco Roglio, a die-cutter veteran, illustrated the functioning of the Serviform EcoPlus, Serviform’s automatic bender, which unites the traditional bending system with an innovative pre-cutting and final shear cutting system. With this machine, created by Serviform for die-cutter manufacturers, participants were able to follow the production of the cutting rules from beginning to end, including their fitting onto a test die-cutter. It was a very useful moment that offered an opportunity to meet an experienced die-cutter fitter, who was able to explain and demonstrate different bending and fitting techniques and the relative maintenance of the materials.

We look forward to seeing you for Module III scheduled to take place in Caravaggio on 20 September!