The planning process: governance of the operational flow

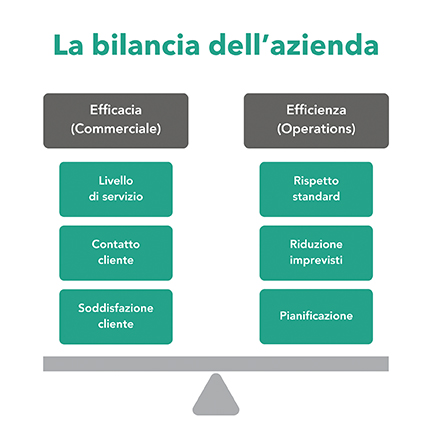

The planning and order management process represents the company’s true balance scale. It is the point of equilibrium between two worlds often in tension: on one side the commercial area, driven by the promise to the customer and by flexibility; on the other the production area, which requires efficiency, order, and optimal saturation of the plants.

When a quotation turns into an order, a journey begins that goes far beyond simple system entry. Every order activates a flow of interdependent activities, from verifying technical feasibility and the availability of cardboard sheets, to machine scheduling, all the way to coordination with logistics and suppliers. An effective planning process means ensuring punctuality, cost sustainability, and consistency between inventory quantities, internal production capacity, and customer expectations. In this sense, planning becomes a true management discipline, not just a bureaucratic task.

The back office: much more than an operational department

All too often, the commercial back office is perceived as a purely executive department, a kind of “customer secretary” tasked with entering orders into the system. Nothing could be more wrong. In the modern model of order management in the corrugated cardboard industry, the back office represents the first safeguard of the quality of the information flow. It is the point where commercial needs are translated into operational actions consistent with production capacity.

Back office objective: to establish and define the customer order delivery date, taking into account various parameters such as: raw material procurement time; production lead times; shipping times; availability of required tools/equipment; warehouse saturation; production saturation and machine load.

In addition, the back office is also responsible for ensuring that the delivery date is respected, or modified if necessary, as well as for managing order changes and progress status. Each operator must have a clear understanding of products, lead times, material availability, warehouse parameters, and must be able to accurately define the type of order to be entered into the system. Only in this way the department can ensure that every order is feasible, optimized, and aligned with company priorities.

The back office, therefore, is not just an executor but an active part in value management: it contributes to efficiency, prevents conflicts between departments, and safeguards the relationship with the customer through clear and consistent communication.

The organizational structure of the planning department

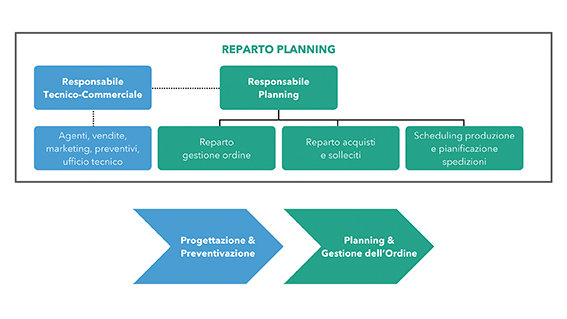

Within a modern industrial organization in the corrugated cardboard sector, the planning department is positioned at the center of the supply chain, acting transversally between commercial and operational functions.

An exemplary organizational chart includes:

- Planning manager at the top, serving as a strategic bridge between sales, purchasing, and operations.

- Order management department, responsible for entering, validating, and monitoring customer orders.

- Purchasing and reminders department, ensuring the availability of raw materials and consumables.

- Production scheduling and shipping planning, which translates the plan into execution and coordinates logistics.

In addition, the planning department must always work in close contact with:

- Technical-commercial department (quotation, design, industrialization), the guardian of technical knowledge and process parameters.

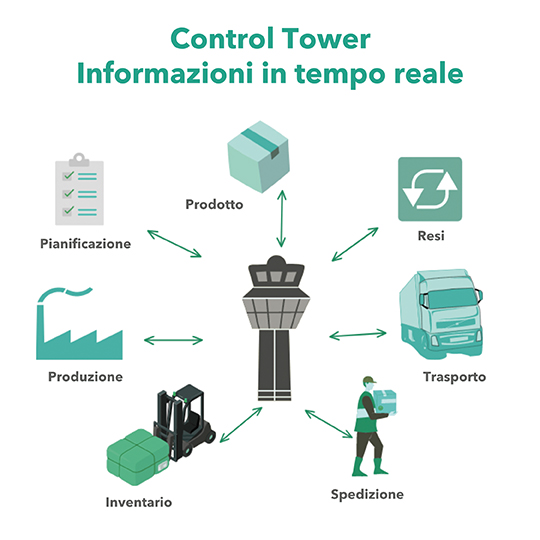

This ecosystem operates with integrated digital tools such as the ERP system, MES/WMS/TMS systems, and “Control Tower” platforms, which provide real-time visibility into job progress and enable proactive management of urgent issues.

Objective of production scheduling: meeting delivery dates and optimizing the job scheduling process, in order to optimize machine setup times.

Objective of shipping scheduling: meeting delivery dates and optimizing routes and load saturation for each trip.

Objective of purchasing: buying corrugated board at the best price and ensuring that suppliers meet delivery lead times.

Key aspects for successful planning

For the planning process to function effectively and sustainably, several key conditions are required:

- Finite-capacity planning: every decision must consider the actual availability of equipment, materials (corrugated sheets), and human resources.

- Cross-functional alignment: sales, production, purchasing, and logistics must operate using shared data, supported by regular meetings and common KPIs.

- Standardized urgency management: the types of box orders that have priority must be defined and shared in advance, without compromising overall efficiency.

- Inventory and lead-time control: maintaining a balance between availability and warehouse turnover, avoiding stock stagnation or stock-outs.

- Digitalization and transparency: modern planning must rely on business intelligence tools and workflow management systems that make every decision traceable.

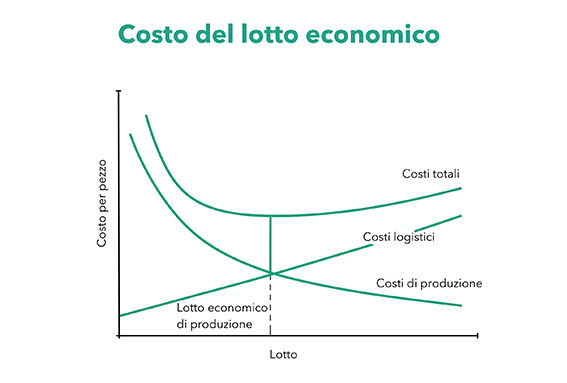

A crucial aspect of planning concerns the definition of the economic production lot. Determining the optimal lot size makes it possible to balance setup costs with those of storing finished goods, avoiding unnecessary accumulation in the warehouse.

A well-calibrated lot keeps production smooth and continuous, ensuring the necessary availability to fulfill orders without generating excess stock. This allows the company to reduce storage costs, increase turnover, and preserve liquidity while maintaining high production efficiency.

The economic lot must be calculated by considering historical consumption of the item (or future consumption forecasts) as well as the supplier’s raw-material delivery time.

In summary, effective planning is the one that transforms complexity into predictability, making what is happening visible and anticipating what might happen.

The role of the planning director

The planning director is the guardian of the company’s operational balance. He coordinates different departments, planning, purchasing, back office, and harmonize their timing, priorities, and resources. His mission is not just to plan, but to govern: to create a coherent flow of information between customer, sales, and operations; to mediate conflicts between efficiency and service; to anticipate capacity or supply-related issues.

Typical KPIs under their responsibility include: on-time delivery; plant saturation and utilization of production capacity; forecast accuracy and reduction of average lead times; stock turnover and optimization of logistics costs.

One of the main challenges for the planning director is ensuring that the customer (and often even their own company, especially the sales department) respects the rules defined within the planning process, such as maximum warehouse storage times for finished goods, or the process for handling urgent orders, to name a few examples. This role is increasingly strategic, requiring a combination of analytical skills, systemic vision, and cross-functional leadership.

The future vision of planning

The future of planning and order management will be increasingly digital, predictive, and integrated. Companies that evolve in this direction will not only reduce inefficiencies but will turn planning into a true competitive advantage.

Control Tower platforms, integration between ERP and execution systems (MES/WMS), and the use of predictive algorithms for inventory management (based on stock-management logic defined in advance according to the company strategy) will enable real-time visibility across the entire flow from order entry to final delivery.

Moreover, E-kanban solutions allow customers and suppliers to connect directly with the company’s information system: simple tools that can deliver significant benefits in terms of service level and customer loyalty.

Looking ahead, the planning director will increasingly become a chief of flow: someone able to read data, interpret trends, guide operational decisions, and keep the promise made to the customer through an agile, transparent, and data-driven production system.

Key principle: sharing the right information.

In conclusion, the planning and order management process is not a simple administrative step: it is the backbone of the modern manufacturing company. Only by understanding that planning means coordinating people, data, and objectives, and not merely “lining up orders”, a company can ensure efficiency, punctuality, and sustainability.

The difference between planning, scheduling, and executing is clear: only by planning correctly is it possible to execute (production) efficiently. In a competitive context such as the corrugated packaging sector, planning is what transforms an order into a kept promise, ensuring efficiency at every level of the organization.