MITO Srl continues to establish itself as a leader in the die-cutting market thanks to its ongoing focus on innovative solutions and the optimization of production processes. The company has developed unique expertise in die-cutting, both for solid board and corrugated cardboard, standing out as a benchmark for competence, quality, and service

The company’s mission is clear: to provide customers with tools and technologies that improve efficiency and enhance the quality of the final product. This vision translates into continuous research and development, which has led MITO to perfect its creasing matrix systems, designed to optimize creasing and ensure faster, more precise machine setups. MITO is not only synonymous with excellence in creasing but also with in-depth knowledge of the entire die-cutting process.

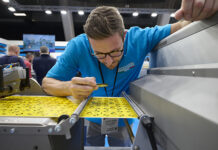

Among the most recent innovations stands out X Rapido, a creasing matrix made from a single extruded piece, with an internally certified channel height to ensure absolute precision and zero-bevelled edges, absolutely unique in the industry. Alongside it is the new Duroprint, made from a high quality Japanese raw material, capable of withstanding long production runs without compromising the precision of the die-cut. Equally important is 8Print, specifically designed for corrugated board, representing a significant step forward in performance and reliability.

In addition to these solutions, MITO continues to introduce new technologies, such as modern rubber profiles, always developed with the goal of meeting the needs of even the most demanding customers. It is thanks to targeted and ongoing investments in R&D that the company maintains its competitive edge, further solidifying its position as a qualitative and innovative leader in the international die-cutting industry.

Another strategic strength is MITO’s membership in the international C&T Matrix group, a partnership that reinforces and expands MITO’s global market presence. Through this synergy, the company benefits from a global network, sharing know-how and production capabilities that result in a more complete and competitive range of solutions.

C&T Matrix is currently the world’s largest producer of sheet metal plates for die-cutting machines, a milestone that represents a fundamental asset for the group. At Clear plant in Valencia, Spain, production capacity has been significantly increased: since the beginning of the year, approximately 10,000 plates have been manufactured, all with certified and guaranteed quality, a result that confirms the strength and reliability of the organization.

But it’s not just about volume, innovation plays a key role as well. The new plates with a certified hardness of 42 HRC have been introduced, particularly aimed at the Northern European market, where very high quality standards and top performance are required. This development represents a concrete response to the demands of an increasingly competitive sector focused on precision, further confirming the group’s ability to anticipate trends and invest in high-value-added products.

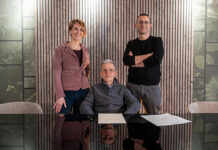

Face to face with Giuseppe Mitolo, CEO of MITO Srl

What is the philosophy guiding MITO in the die-cutting sector?

“Our philosophy is simple and clear: combining expertise, quality, and service. We believe every innovation must deliver real value to the customer, improving not only the final product but also the efficiency of production processes”.

What role does research and development play in the company’s growth?

“It’s the beating heart of our business. Without research, there is no future. Our creasing systems, like X Rapido or Duroprint, are the result of continuous investments that allow us to anticipate market needs and deliver ever higher-performing solutions”.

What are the benefits of being part of the C&T Matrix group?

“Being part of an international group gives us a global perspective and access to unique resources and production capabilities. The fact that we are now the largest producers of plates is a point of pride, but also a responsibility, it means the market recognizes our commitment and the quality of our products”.

What’s the next international trade fair you’ll attend?

“We’ll be attending the Dietech fair in Prague on October 16–17, along with the entire C&T Matrix group. It’s a key event for our industry and a great opportunity to showcase our innovations, engage with professionals in the field, and once again demonstrate MITO’s ability to innovate and deliver value-driven solutions”.

How do you see MITO’s future?

“I see a future full of challenges and opportunities. We will continue to invest in research and innovation, because that’s the only way to maintain our leadership and keep delivering high-value solutions to our customers. Our mission remains the same: transforming the complexity of die-cutting into a simple and efficient process”.