The web-processing industry has embraced the trends of Industry 4.0 and is increasingly using real-time data from production to boost efficiency. That explains the great interest in the Converting 4.0 exhibits that BST eltromat International presented in the fall of 2019 at various events in cooperation with machine manufacturers. “Faster machine setup, minimized waste, higher energy efficiency and consistently high-quality production – we demonstrated the benefits that result from the integration of our quality assurance systems in fully digitized and interconnected production processes,” says BST eltromat Innovation Manager Dr. Michael Dattner, explaining the objective the company is pursuing in its Converting 4.0 activities.

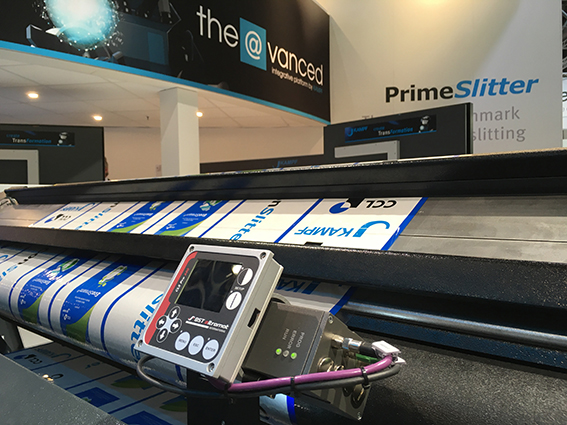

BST eltromat is a founding member of the Converting 4.0 network initiated by the company Kampf Schneid- und Wickeltechnik GmbH at the International Converting Exhibition (ICE) 2017. At this year’s K plastics and rubber exhibition in Düsseldorf, the two companies presented a simulation that showed the interaction of a CLS PRO 600 digital line and contrast sensor from BST eltromat with a slitting machine typ ConSlitter and the the@vanced integrated platform from Kampf Schneid- und Wickeltechnik. The integration allows the sensor technology and the motor-driven knife axle of the slitter to be set up automatically. With this approach, the knives are no longer aligned with the sensor. Instead, the designs on the webs are aligned with the knife axle. The sensor automatically moves to the preset lines and then supplies information useful for optimizing the cutting process.

Maik Krüger, Strategic Product Manager at Kampf Schneid- und Wickeltechnik, describes the most important benefits of this integration, saying, “The automatic alignment of the cutting patterns simplifies the cutting process and greatly reduces setup times. It also eliminates sources of error, which helps to prevent waste.” The production data for the slitting is transferred directly to the system controls from an ERP system.

On November 12 to 13, BST eltromat took part in the fourth meeting of the Converting 4.0 network at Windmöller & Hölscher (W&H) in Lengerich. More than 100 visitors attended the event, which was headlined “Boosting Efficiency across Value Chains” and dealt with process data communication across process boundaries. Here, too, BST eltromat presented solutions and ideas involving the integration of quality assurance with upstream and downstream production processes. The company highlighted how bringing together quality data leads to greater efficiency and security as well as more convenience and sustainability, provided the information is available in synchronized form. “Often, companies already have access to ‘highly relevant’ data. But this data isn’t used because the standardized interfaces and formats that are needed haven’t been established yet,” says Dattner. “I was really pleased with the in-depth discussion on cloud solutions for data storage and cloud computing at our booth during the in-house W&H exhibition. Dr. Christoph Legat from our sister company Hekuma was one of those who spoke out in favor of an independent platform concept,” says Dattner. Thanks to the intense working atmosphere of the network meeting, he actually had the opportunity for direct exchanges with every participant, he says.

On October 20, during the “Recyclates in Products” segment of the VDMA Circular Economy Forum at the K Show in Düsseldorf, Dattner showed how integrated Converting 4.0 processes support the production of innovative plastic materials that can be used for recyclable or biodegradable packaging, for example. “The new materials have to offer the same quality and functionality as the plastic materials previously used to make packaging. But they have special properties that impose new requirements on the web guiding or the surface and print inspection, for example. We meet these requirements in part with adjusted web guiding systems, sensors and inspection systems,” said Dattner in his presentation on “Quality Assurance Tailored to Recyclate-Based Products.” Here, too, Converting 4.0 enables optimizations across processes.