Can a simple cardboard box become a key player in the circular economy and contribute to the ecological transition of customers? The answer lies in the paper-based solutions designed by the multinational, world leader in the packaging sector, Smurfit Westrock Italia.

Three letters – BPP – one mission: to create packaging that is friendly to the environment and our planet, Better Planet Packaging. An ambitious goal that Smurfit Westrock Italy has been pursuing since 2018, the year it launched the initiative, with a clear purpose: to create packaging capable of replacing, whenever possible, materials with a high environmental impact such as plastic and polystyrene, in favour of paper and its derivatives. A strategy that today has also become a necessity for goods-producing companies, with the entry into force of PPWR, the European Packaging Waste Regulation, which promotes materials with minimal environmental impact, such as paper and cardboard.

A network of eco-designers

To achieve this goal, Smurfit Westrock can rely on a global network of over 2,000 designers specialized in eco-packaging and on a database of tens of thousands of completed projects, best cases available to clients. In Italy, the multinational counts on two research and development centers where cutting-edge tools are available to clients to co-design the packaging of the future. One is located in Pastrengo (Verona), hosting the national Experience Centre, with a specific focus on the Triveneto and Emilia Romagna areas. The second is in Asti, inside one of the multinational’s main Italian plants, where a Solution Centre was recently inaugurated, designed primarily to offer its services to clients in the Northwest region.

Successful case histories

Among the most recent examples of Better Planet Packaging are two solutions designed for clients in the food industry, developed at the Orsenigo plant in the Como area, which also houses the Cans line (producing cardboard tubes and cans) and the Machine Systems division dedicated to packaging machinery.

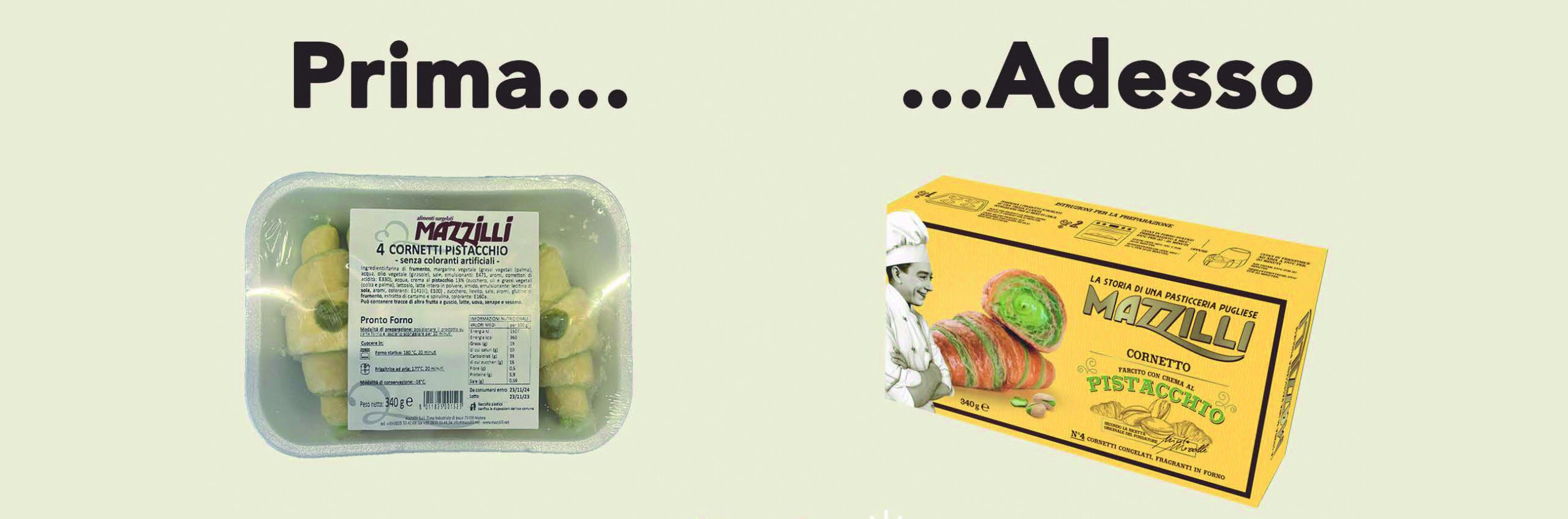

The company Mazzilli, founded 50 years ago as a traditional pastry shop in Gravina di Puglia and now a well-established national player in the frozen food sector, chose paper-based packaging. Mazzilli operates in retail, large-scale distribution (GDO), and Horeca channels, mainly in Central and Southern Italy, as well as in some European countries. The hero product of the range is the frozen croissant in many variants, alongside other sweet specialties. Until last year, for its frozen products, the company used a polystyrene tray sealed with shrink plastic. Today, all Mazzilli specialties are packaged on a polyethylene-coated cardboard tray, that is cardboard laminated with a thin layer of polyethylene: a minimal quantity, just over 5%, which makes the tray recyclable within the paper recycling stream and qualifies for the lowest Conai contribution. The tray is contained in a cardboard box as well. This solution has been adopted since early 2025 for all packaging, a change that results in a great achievement: the elimination of over 21 tons of plastic material.

On the shelves of Coop supermarkets and hypermarkets, two new multi-pack snack packages from the Spesotti line, the Trancini, are on sale, featuring a cardboard box replacing the traditional plastic-based flow pack bag. The project is backed by Freddi Dolciaria, based in Castiglione delle Stiviere (Mantua). For the new ten-piece snack boxes, recycled cardboard was used, printed and die-cut. This investment resulted in a major achievement: the elimination of over 4 tons of plastic, equal to a 48% saving of total flow pack, which is now only used for single snack packages. This choice has been appreciated by consumers and rewarded by the market: thanks to the new packaging, sales increased by 33%.

“Projects like these are a concrete witness to our mission: supporting customers in an ecological transition for everyone’s benefit”, comments Gianluca Castellini, CEO of Smurfit Westrock Italy. “They represent an excellent example of how different players in the same supply chain can work together sharing a strategy and a goal: reducing the environmental impact of packaging and increasing its recyclability. They are also clear confirmation of how packaging is increasingly becoming a strategic lever in brand reputation and, in particular, how paper-based packaging can be a significant factor in consumer choice and become a driving force in revolutionizing their habits”.