Everything starts with cardboard: Scatolificio Ceriana, with 70 employees and headquarters in Settimo di Pescantina (VR), is specialized in the production of corrugated cardboard packaging using various technologies for different sectors including food, automotive and pharmaceutical. The installation of the HP PageWide C550 digital press with water-based inks stimulated the need to create an internal pre-press department and the company chose Hybrid Software for its flexibility, modularity, precision and speed in color management

Scatolificio Ceriana’s decision to invest in the HP PageWide C550 in 2023 has been taken because the company sought to expand its production offer to respond to customization needs and to access new applications; moreover, water-based ink technology allows to offer sustainable, recyclable and compostable packaging.

“After the significant investment with HP, we consulted with them to find out what was needed to best tackle this new digital adventure and the advice was clear, we had to set up an internal pre-press department, to have a completely digital workflow in-house. After listening to the proposals of various suppliers, in the end I feel I made a somewhat unusual choice, but I chose Packz by Hybrid Software. I liked it immediately because it was fresher and more up-to-date. I must also admit that the positive opinions of pre-press services we work with every day, who were absolutely satisfied with its performance, also influenced our choice”, explains Giovanni Barichello, co-owner of Scatolificio Ceriana with his brother Marco.

Obviously Ceriana doesn’t only use the two installed standard Packz for the digital printing workflow, but the whole process has been internalized, so it is also used for the pre-press of jobs printed in flexo and/or offset, even if only for file preparation, because the file then is sent to external pre-press services for platemaking.

Higher level of efficiency

The support by Hybrid Software after installation was very important, especially because Ceriana decided to train a person who could dedicate himself exclusively to the management of pre-press for the digital printing machine, for a more secure and controlled workflow.

“Packz is different from other editors because you don’t need other software for file management, everything is included and this naturally allows to create higher standardization, because once you’ve acquired the approach and methodologies, and done the work of classification, standards and profiles, everything runs smoothly”, adds Giovanni.

He recalls the simplicity of reading/creating the profile for digital printing and the possibility of managing the conversion directly through pre-press editor Packz, emphasizing the speed and control for creation of PDF draft for the customer, through dynamic tools and objects always directly in Packz.

It was also installed the Advanced Color module that provides an instant preview of the printed artwork under different printing conditions, including spot colors.

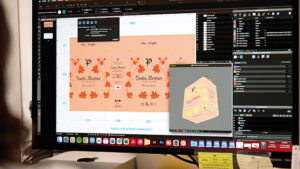

And what about the almost magical iC3D: a single application that uses a simple Illustrator or PDF file for photorealistic results in just a few minutes, chosen by Ceriana because it is essential for their daily work. It features patented Smart Mesh that allows to slide instantly graphics over models without needing tedious UVW texture co-ordinate mapping. You can create a 3D model that allows to have greater control and reduce the time and costs associated with creating a sample for the customer. “Once the pre-press file has been created, we can produce a three-dimensional model that we can show to the customer, who can interact with it as if it were really in his hands, even turning it inside out; this possibility also helps in the process of checking the graphic layout, avoiding complaints, problems and remakes”, explains Giovanni.

Perfect digital color management with ColorLogic

Four years ago Hybrid Software Group PLC acquired the German company ColorLogic, which became the fifth operating company of Hybrid Software Group, joining Global Graphics Software, Hybrid Software, Meteor Inkjet and Xitron.

Ceriana considered it essential to acquire ColorLogic tools: “when we use the HP machine we print in pure four-color process, without a fifth or sixth color, so we have a fairly narrow color gamut, but thanks to this software we are able to achieve excellent color reproduction because we can quickly and reliably convert Pantones directly from the front-end of the digital press, thanks to the integration of the ColorLogic profile in HP that allows to print without having to go through a conversion software between Packz pre-press editor and the press, a fundamental aspect because it eliminates a step and a possible bottleneck in production”, says Giovanni.

Ceriana chose ColorAnt and CoPrA. ColorAnt is a tool that measures test charts, corrects and optimizes measurement data. Additional features include editing primary colors and media, tonal value corrections, CxF/X-4 data insertion and comprehensive reporting. ColorAnt can be integrated into any workflow to improve the quality of any ICC profile.

CoPrA is a control center for any profiling activity: ICC Printer profiles, DeviceLink for all color space combinations and high quality SaveInk (gray, RGB, CMY, CMYK and multicolor color spaces); there is also a flexo printing function to create the ideal flexo profiles.

A targeted decision to guarantee consistent quality and punctual deliveries

“We are very satisfied with the investment we made with Hybrid Software, we work better and I definitely recommend Hybrid Software as a partner and supplier of solutions that really do what they say: they are tools that allow us to create well-made products, printed using the latest technology, but replicable over time with the same quality”, concludes Giovanni.