Heidelberger Druckmaschinen AG (HEIDELBERG) is committed to fully automating the print production value chain so that printing becomes a largely autonomous process. While digitalization initially focused on prepress, there is still significant potential for efficiency improvements.

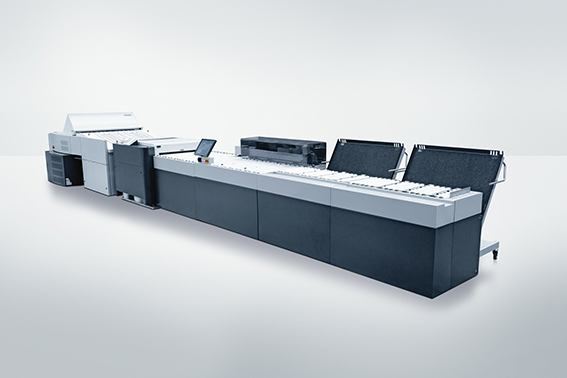

HEIDELBERG is advancing computer-to-plate (CtP) automation with the launch of the Compact Pallet Loader (CPL) and Compact Bender, integrating them into a single CtP workflow.

Paired with the Suprasetter 106/A106 platesetter models, the CPL allows fully automatic loading of printing plates into the systems while occupying minimal space. The CPL covers all Suprasetter performance levels, including the top-of-the-line model capable of 55 plates per hour. Integrated into the Prinect workflow, the CPL autonomously supplies the CtP system with plates according to the job structure.

The new Compact Bender completes the fully automated processing of offset plates. With an optional barcode recognition feature, it can deliver plates sorted by press, job, and plate set without any manual intervention. “By systematically pursuing end-to-end automation in prepress, HEIDELBERG reinforces its role as a full-range supplier for packaging, commercial, and label production. Print shops can leverage the Compact Pallet Loader and Compact Bender to reduce operational and personnel costs while addressing the skills shortage,” says Dr. David Schmedding, Chief Technology & Sales Officer at HEIDELBERG.

Autonomous and Contact-Free Plate Handling

The Compact Pallet Loader integrates seamlessly with the CtP system and requires very little additional space. It can image 1,200 printing plates in the 650 × 750 mm to 1,050 × 1,200 mm range in continuous, pallet-by-pallet operation. Together with the Compact Bender, the complete plate production process—from platesetter loading to plate bending—becomes largely autonomous. Suprasetter 106/A106 models manufactured since 2017 can also be retrofitted with a CPL.

The Compact Pallet Loader addresses a gap in CtP technology. In its basic configuration, the Suprasetter 106/A106 is automatically loaded using the Dual Cassette Loader, which holds 100 plates per cassette. At the upper end, the Auto Pallet Loader (APL) accommodates up to 1,500 plates of uniform format. All HEIDELBERG solutions ensure fully automated, contact-free plate handling with minimal personnel requirements while offering excellent flexibility in terms of format and production volume. Modules can be scaled or combined according to requirements.

Pilot User Druckstudio GmbH Increases Efficiency with the CPL

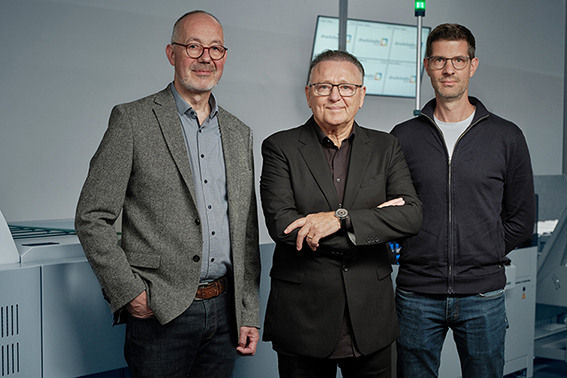

Druckstudio GmbH in Düsseldorf, a high-quality commercial and packaging print provider for automotive, fashion, cosmetics, energy, advertising, and luxury goods clients, is one pilot user of the new Compact Pallet Loader. The company emphasizes sustainable and resource-efficient production.

A few weeks ago, Druckstudio GmbH commissioned the CPL together with a new Suprasetter 106 and a Speedmaster XL 106-8-P, complementing its existing Speedmaster XL 106-5+L. The growing plate processing demands prompted the company to equip the Suprasetter 106 with the Compact Pallet Loader.

Werner Drechsler, founder and Managing Partner of Druckstudio GmbH, states: “The HEIDELBERG Compact Pallet Loader, together with the new bending and sorting line, ensures smooth production. Tasks like manually filling plate cassettes and bending imaged plates used to take a lot of time. Automation has significantly increased efficiency and boosted our productivity.”

In April 2024, Druckstudio GmbH also entrusted HEIDELBERG with managing its consumables warehouse via the Vendor Managed Inventory (VMI) system. The system automatically replenishes consumables when minimum inventory levels are reached.