Nexpack is a consulting advisor specializing in the corrugated cardboard and packaging sector. Its distinctive feature? Not just tailoring and improving organizational processes, but also enhancing and training involved resources through its proprietary Mentorcoaching® methodology

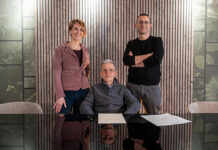

“Many reorganization projects only bring short-term benefits because they fail to adapt over time to the evolution of the market and the company. This is why we often intervene in what is known as the chain of command, a weak point especially in family-owned SMEs”, notes Francesco Pagliarini, CEO of Nexpack.

Nexpack believes that organizational structure is not a “Linus blanket” that can be imposed top-down with so-called “efficiency mantras,” magically making everything work. That approach isn’t enough, beacuse it would be mere academic theory: attractive, but fragile over time.

On the contrary, even when working with multinational companies, Nexpack is often called upon to mediate an organizational and commercial setup with an international footprint that is not entirely suited to the specific needs of the Italian market. In essence, you cannot simply “mirror” an organization from one context to another.

An organization moves in the right direction only when the right people are placed in the right roles at the right time. People who, in addition to following the correct work protocols, are suitable and properly trained for their assigned positions.

Mentorcoaching®: training and intergenerational change

This is the tool used by Nexpack through its NexAcademy division, dedicated to training and development. It combines mentoring and coaching approaches to foster real, hands-on development of company resources. The goal is simple: to transfer field-tested best practices using a practical, applicable approach, not theoretical, but real-world ready. The first step is an analysis to define objectives, needs, and expectations of the company and/or the individual, followed by the design of a customized development plan. At the end of the process, an evaluation report is produced to assess the results achieved. A follow-up phase is also planned after the initial process, to ensure that changes and improvements are consolidated. “Even though the issues encountered in companies often resemble one another, our protocols are always tailored to the specific company context”, emphasizes Pagliarini.

Training and intergenerational change

“Training support becomes even more important when we consider that the average age of management in the sector has increased by about 6 to 7 years between 2010 and 2025”. highlights Pagliarini.

“During generational transitions, the most common challenges include difficulties in passing on the seniors’ knowledge, the risk of communication breakdowns, and unclear job roles. This can lead to resistance to change, silent conflicts, or gaps in responsibility. To turn generational change from a problem into an opportunity, we aim to strengthen role awareness, helping individuals express their unique qualities based on personality and professional experience. We do this through individual coaching programs to improve internal communication and develop soft skills”, add Barbara Fossi and Marco Susini, both Project Managers at Nexpack.

Future challenges: logistics, innovation, and energy

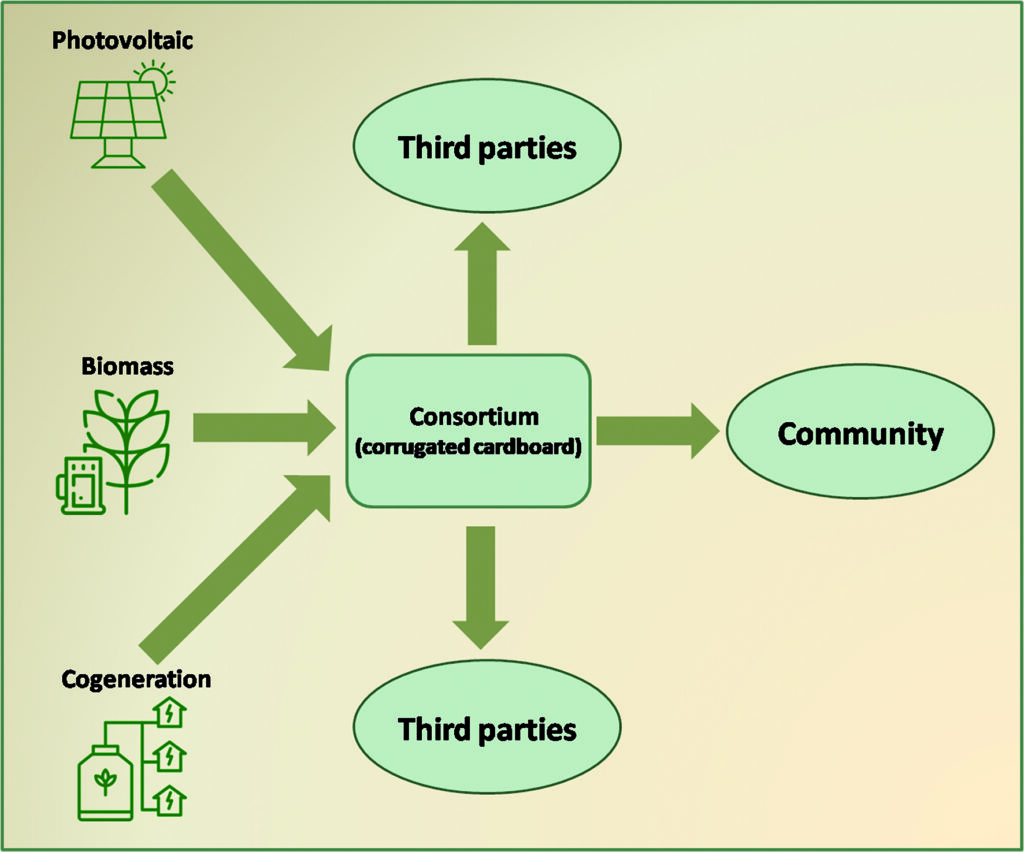

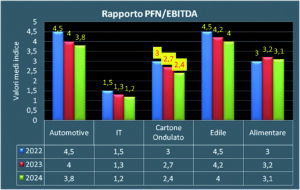

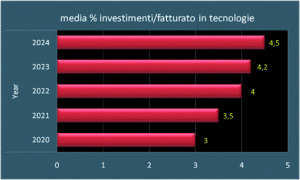

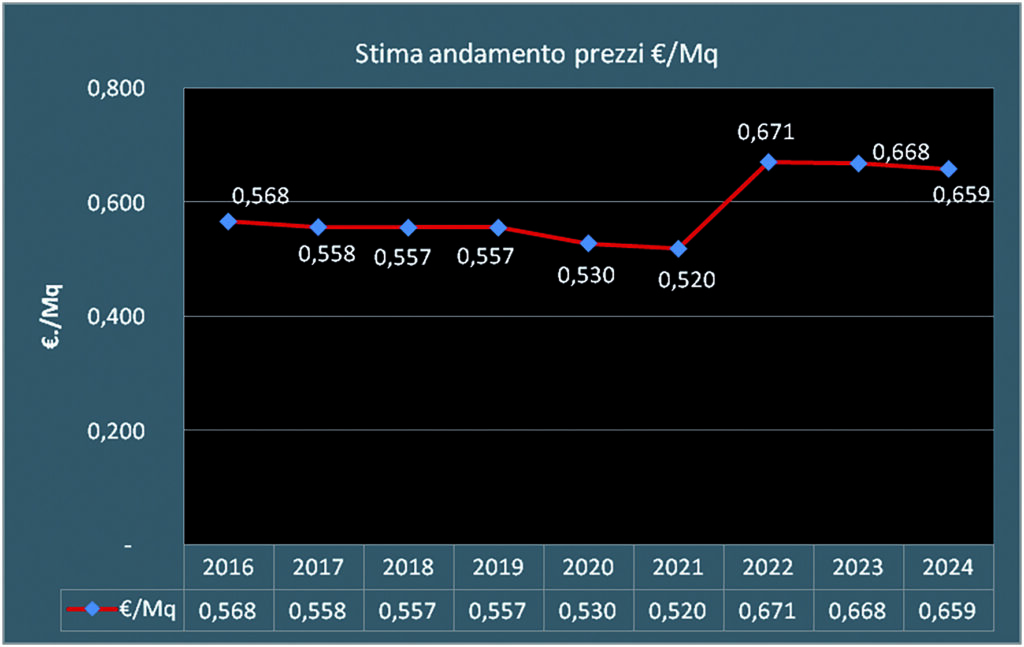

“The corrugated cardboard industry, which is in good industrial and economic health despite alternating years, has invested over the past 10 years in continuous machines, corrugators, casemakers, flatbed or rotary die-cutting lines, digital printing lines, etc. Probably, the challenge of the coming years will lie in logistics, procurement, warehouse handling and automation, product innovation, the ability to convert sectors still relatively insensitive to the use of cardboard packaging, improving the performance and professionalism of sales structures, but also in producing energy – yes, actual energy!” says Pagliarini, putting forward an interesting proposal: paper mills and corrugated cardboard plants could set up industrial energy consortia (CER), investing not only in photovoltaic systems, but also in biomass, high-efficiency cogeneration, or even small-scale wind power, becoming local energy hubs that provide clean energy not only for themselves but also for third parties.

Of course, these are demanding and costly projects, and they require a collaborative approach, even among competitors, potentially facilitated by industry associations. One model could involve 10 medium-to-large companies located across an interregional production district, aiming to generate approximately 24 GWh/year from photovoltaic systems; 140 GWh/year from distributed cogeneration (CHP) across 10 plants powered by gas/methane (with a future outlook on biomethane or hydrogen); 35 GWh/year of green energy from biomass by thermally recovering production waste (such as cardboard scraps and cellulose) for a total of around 200 GWh/year.

“Such a consortium would make the Italian corrugated cardboard sector more competitive, sustainable, resilient, and less dependent on vertical suppliers,” concludes Pagliarini.

In summary, Nexpack follows an integrated approach that combines organization, governance, and people development, with close attention to future challenges and business sustainability.