Today, digital transformation and embellishment are no longer cutting-edge options but have become the standard. Over the past two years, Cartes, a global leader in label finishing machines, has installed numerous lines equipped with inkjet embellishment units combined with laser cutting systems. The company now boasts customers in over 100 countries and an impressive installed base of more than 4,300 machines. At the core of Cartes’ solutions lies modularity, which has boosted sales by 35% and enables delivery times of just three months

Founded in the early 1970s in Moglia, Mantua province, Cartes was born in the heart of Italy’s precision mechanics industry, initially developing technologies for hot stamping and screen printing. For over three decades, it was a key reference in analog finishing.

In 1999, Cartes took a bold step and carried out its first true “Copernican revolution”, going against the current: it was the world’s first company in the sector to introduce laser die-cutting for labels. “At that time, anyone talking about laser die-cutting was considered heretical, but many companies believed in us. Some of those very first laser machines are still fully operational after 27 years”, recalls Mario Lodi, company founder. Today, more than 600 laser machines are installed across 100 countries.

While digital toner and inkjet printing quickly spread across the label market, the path was different for digital finishing, mainly due to the technical complexity of processes such as varnishing, hot foil, die-cutting, and embellishment.

While digital toner and inkjet printing quickly spread across the label market, the path was different for digital finishing, mainly due to the technical complexity of processes such as varnishing, hot foil, die-cutting, and embellishment.

The wide range of materials, the precision required, and the expected visual impact restricted this sector to only a few players. Leveraging its strong analog background, Cartes was one of the few companies able to bridge this technological gap.

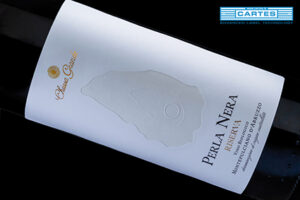

In 2020, after years of in-house research, Cartes launched the JET D-Screen module, a high-definition inkjet system designed to reproduce tactile and visual effects similar to embossing, Braille, high-build varnishes, and 3D metallic gold.

JET D-Screen perfectly complements other Cartes units such as flexo, screen printing, hot stamping, embossing, flatbed or semi-rotary die-cutting, multilayer label application, and many more.

The modular architecture of Cartes lines allows for extreme customization of each machine, which can also be upgraded after installation.

JET D-Screen becomes the standard configuration

Within just a few years, the configuration combining laser cutting and digital screen printing has evolved from a pioneering choice into the industry’s de facto standard. 2024 marked a significant increase in demand for these technologies, both from traditional printers and online operators. “What seemed like a gamble back in 2020 has now become common practice”, says Enrica Lodi, Cartes Marketing Manager. “More and more customers are choosing to configure their machines with a JET D-Screen unit. It’s a technology that makes it possible to produce unique labels, just in time”.

Within just a few years, the configuration combining laser cutting and digital screen printing has evolved from a pioneering choice into the industry’s de facto standard. 2024 marked a significant increase in demand for these technologies, both from traditional printers and online operators. “What seemed like a gamble back in 2020 has now become common practice”, says Enrica Lodi, Cartes Marketing Manager. “More and more customers are choosing to configure their machines with a JET D-Screen unit. It’s a technology that makes it possible to produce unique labels, just in time”.

Among the companies that have adopted Cartes’ digital embellishment and laser die-cutting solutions are leading names such as Graficas Tomelloso (Spain), Multistampa (Italy), Imoco (Italy), Sovemec (Italy), Etiquel (Portugal), LP2i (France), Paragon Label (USA), Info Label (USA), as well as online printers including Labeldoo (Italy), Etichette l’Immagine – Tikedo Group (Italy), Sticker Mule (Italy), Labelprint24 – All4Labels Group (Germany), and many others.

Cartes continues to invest in improving and integrating digital technologies that reduce time, waste, and energy consumption–ultimately lowering operating costs–while achieving ever higher performance and sustainability. The flexibility offered by the GT360 and GEMINI systems, combined with the reliability of Cartes’ laser and inkjet embellishment solutions, has established the company as a benchmark for producing premium and complex labels in a single pass.

The company operates a 12,000 m² facility with 60 specialized technicians, and it also maintains a subsidiary in Red Bank, New Jersey, as well as a commercial branch in Guadalajara, Mexico.

Cartes at Labelexpo Barcelona

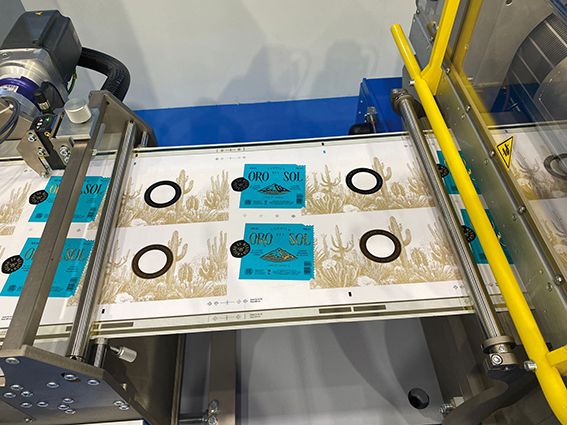

At the recent Labelexpo, Cartes showcased seven machines dedicated to premium converting and embellishment.

On display was the GT368WSSHSJRH–the world’s most comprehensive label embellishment and finishing machine–featuring 8 units and multiple accessories. During the show, it transformed plain paper into high-quality premium labels in a single pass; this label was developed in collaboration with Basile ADV and Sovemec.

Also exhibited was the GT365WHSSR, a more compact label finishing and embellishment solution, offering the extreme modularity that only Cartes can guarantee, delivering the highest finishing precision available on the market.

Key technologies included the award-winning JET D-Screen for digital embellishment, ideal for multilayer effects, spot coating, complex tactile reliefs, Braille printing, and 3D metallic doming. Combined with laser die-cutting and converting on the GE363VJL, which, together with the turret and the core cutter cobot, it provides the perfect solution for producing, fully automatically ,high-end labels instantly and sustainably, without tooling.

JET D-Screen was also featured on the GE363VJR with semi-rotary die-cutting, equipped with the exclusive Air Gap and Image Distortion systems.

The GE362WL-DUAL was also presented, featuring the fastest laser converting system on the market and the only unlimited-lifetime laser source, enhanced by the patented Invisible Laser Cutting (ILC) system.

The GE361L-STAR, Cartes’ entry-level laser die-cutting machine, was showcased as well. It offers a more compact configuration, guaranteed by Cartes quality and equally effective performance. It is also equipped with an unlimited-lifetime source.

The Cartes booth, one of the busiest throughout the exhibition, offered visitors live demonstrations of cutting-edge technologies, allowing them to directly evaluate print quality, embellishment, finishing, performance, and modularity. Attendees also discovered new modules, upgrades, and customized solutions for complex applications such as premium or just-in-time labels.

“We are no longer in an experimental phase. Digital transformation in labels is no longer a gamble, it has become the new operational standard for converters who want to stay competitive by delivering ever more unique and cutting-edge products”, Enrica Lodi concludes with firmness.