Valco Melton will showcase at Ipack-Ima, Hall 10 Stand D49, its latest hot melt melters designed specifically for the packaging industry. The Kube series adhesive melters lead a new generation of energy-efficient melters that optimize the heating process. Enhanced insulation minimizes energy loss, while the optional automatic adhesive feeding system eliminates the need for manual refill operations. These features improve operator safety and reduce adhesive time in the tank, which prevents charring.

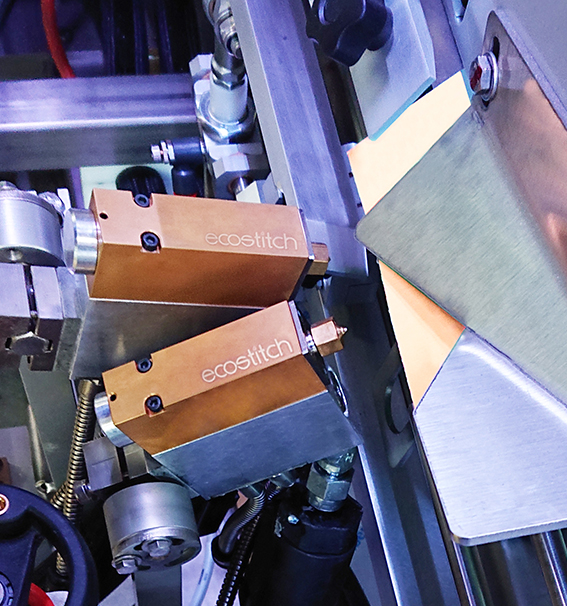

In addition, visitors will be able to experience a live demonstration of our EcoStitch applicator, which has become the proven standard in electric gluing, renowned in the packaging industry for its durability and efficiency. Its precise adhesive control delivers accurate dot patterns, cuts adhesive use by up to 75%, and lowers costs, offering a quick return on investment (ROI). By eliminating the compressed-air and incorporating fewer moving parts, this solution significantly minimizes downtime and spare parts consumption. Therefore, the all-electric EcoStitch technology enables a significant reduction in adhesive consumption and machine downtime, while ensuring the delivery of high-quality products without delays.

This year, Valco Melton shares its exhibition space with ERO Gluing Systems, its Italian subsidiary specializing in cold glue application and quality assurance systems. Together, they bring a team of experts in hot melt and cold glue dispensing technology, offering complete and highly professional support for the converting industry.