Last April, Siemens previewed the main themes and technologies that will be showcased at the upcoming Ipack-Ima 2025. The event was held at Casa Siemens and welcomed numerous guests, introduced by Floriano Masoero, CEO of Siemens Italy. Also present two Siemens clients from the sector, Telematic and Mad. The long-standing collaboration between Mad and Siemens will be highlighted at Ipack-Ima 2025, where a pilot line will be created within the Smart Factory organized by the fair, bringing together partnerships and technologies.

In his opening speech, CEO Floriano Masoero emphasized Siemens’ simple yet essential strategy: combining the real and digital world, a concept clearly represented by the symbol of infinity. The company’s mission is to enable every organization to accelerate its digital and sustainability transformation, which requires the integration of hardware and software. A key element in this is Siemens Xcelerator, Siemens’ open digital platform that includes digital and IoT-enabled solutions from both Siemens and certified partners.

Today, data collection and management are essential in any context, with the aim of transforming data into useful insights. This is the foundation of Siemens Industrial Copilot, developed to leverage data and improve human-machine collaboration. It is the first industrial assistant based on generative Industrial AI, designed to revolutionize production processes. Over 100 customers in Europe and the United States are already using it to improve efficiency, reduce downtime, and address labor shortages.

Masoero also highlighted the Pack Team, a group of Siemens experts with specific knowledge of the packaging market, the Application Engineers at the Packaging Competence Center in Bologna, and the Digital EXperience Center (DEX), where it is possible to experience and test the most innovative technologies supporting digital transformation in manufacturing. At DEX, real machines and applications interact to showcase the benefits of innovation and digitalization, and to develop tailor-made solutions for both large companies and SMEs.

Concrete application of the digital twin: Siemens and Mad Automation collaborate to transform industry

Mad Automation is a company based in Arezzo, Italy, that has been operating since 2007 in the field of design and manufacturing of automated systems for packaging, industrial logistics, and software development sectors. Its core business lies in the production of end-of-line systems, with particular focus on cartoning machines, case packers, palletizing systems, and laser-guided automated vehicles.

The collaboration between Mad and Siemens has been ongoing for years and is reaffirmed at Ipack-Ima 2025, where, within the Smart Factory, Mad has been selected as the builder for the end-of-line systems. The company will showcase a tWrap case packer for packing 250g bags of coffee beans, a collaborative palletizer, and an LGV MAD 3000s shuttle for the automated handling of packed and labeled pallets. The result will be a simulation of a real production line, with Siemens serving as the technology consultant.

Mad’s booth will also be the stage for their latest project developed using Siemens Digital Twin technology for a client in the industrial baking sector, which sought to increase productivity and automation levels. The Digital Twin was used throughout the design and implementation phases, allowing the simulation of potential issues and enabling the company to address challenges in the development of a new prototype before physically producing it.

Thanks to this Siemens solution, Mad was able to reduce waste, both in terms of time/labor and material, and build an innovative plant that goes beyond simply training, filling, and sealing cartons. The system also automates the loading of die-cut cartons (not folded cartons) into the magazine. It incorporates predictive maintenance controls and can optimize and forecast actual performance both in the present and in the future, thanks to the data provided by the digital twin.

La Molisana relies on Siemens and selematic to improve efficiency and reliability of production processes

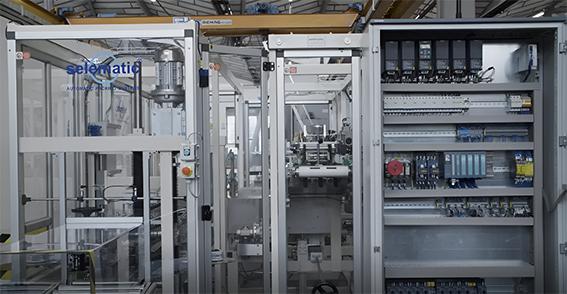

Selematic specializes in the design and creation of customized automation systems for the packaging and handling of pre-packaged products. With a strong focus on the dry and fresh pasta market, Selematic also serves industries such as legumes, dried fruit, confectionery, pet food, and disposable products. In its growth journey, Siemens has emerged as a strategic technology partner: from integrating SINAMICS drives to managing machines via SIMATIC controllers, and implementing IoT technologies and predictive maintenance based on Industrial Edge. Thanks to Siemens, Selematic has developed increasingly optimized machines with high performance.

A concrete example of this collaboration between Siemens and Selematic is the project developed for La Molisana, aimed at optimizing machine maintenance management, reducing unexpected downtime, and increasing productivity. The solution adopted by Selematic involved integrating Siemens’ Industrial Edge platform, one of the company’s new IoT technologies. This platform uses artificial intelligence algorithms to collect and analyze real-time machine data. After a thorough analysis of La Molisana’s needs, Siemens and Selematic identified a series of key parameters to monitor, including mechanical, electrical, and vacuum system variables. Thanks to Siemens’ Industrial Edge apps and an interactive dashboard, La Molisana could monitor the real-time performance of its machines and receive timely notifications in case of anomalies.

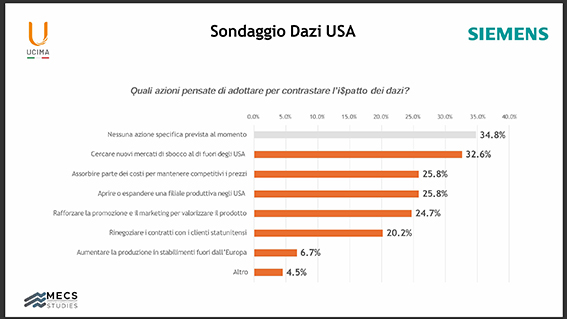

The Italian packaging industry is solid and adaptable

During the event, Luca Baraldi, Head of Mecs, Ucima’s Studies Office, stated that, based on the collected data, export is a strong point in Europe and Latin America. The pre-final 2024 turnover for the packaging sector amounts to a total of 8 billion (2.2 billion for the domestic market and 7.6 billion for exports). Mecs-Ucima also interviewed about a hundred companies regarding their expectations concerning the impact of U.S. tariffs. When asked about the influence of tariffs on business, 34.3% responded that negotiations are slowing down, while 27.6% said there is no impact. However, in the long term, 32.6% expect more difficulty access to U.S. market, and 23.6% foresee a significant reduction in exports to the U.S. The graph shows the actions that companies plan to take to counteract the impact of tariffs. In any case, despite the many uncertainties, the packaging sector has the strength and expertise to react, protect itself, and continue growing.